V.Ryan © 2019

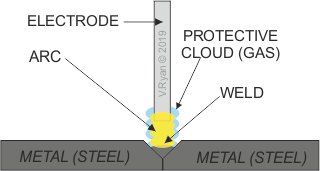

Electric Arc welding is a fabrication technique, through which metals are joined permanently. The metal to be welded is clamped in the earthing /ground clamp. An electrode is gripped in the electrode holder. A suitable ‘current’ is selected, by turning the current selector handwheel. When the electrode comes into contact with the metal, an ‘electric arc’ is formed, creating immense heat. The ‘welder’ must then maintain a small gap between the electrode and the metal (current continues to flow across the gap, creating the high temperatures). At this point both the electrode and metal surface melt and fuse together, creating a welded joint. This sounds an easy process, but it takes professional instruction and hours of practice, to the technique.

The electrode should be approximately the same diameter, as the metal to be welded. The current is selected according to a table of recommended settings, which is normally printed on the top or side of the welding unit.

Safety equipment: Suitable protective welding visor, to protect from Arc UV light, welding gauntlets, protective apron and gloves / gauntlets. Welding curtains should be set up around the welding area, to protect people working in the surrounding space, from the effects of Arc UV light.

The electrode is coated in ‘flux’, which emits a cloud of protective gas, when welding is taking place. This protects the area being welded, from atmospheric contamination, which could interfere with the welding process.