| CLICK HERE FOR INDEX PAGE |

| |

| STAGES IN THE FORGING AN EYE USING A JIG / FORMER |

V.Ryan © 2020 |

| |

| To mass produce the same forged part, requiring an ‘eye’, would be time consuming. A simple but effective jig / former can be made, if there is a need to manufacture large numbers. |

| |

|

|

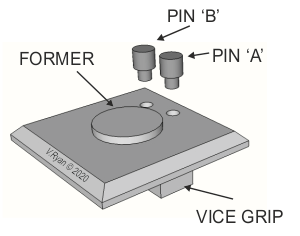

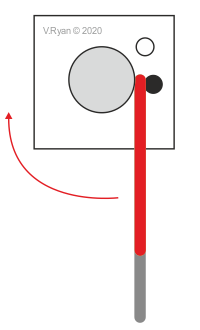

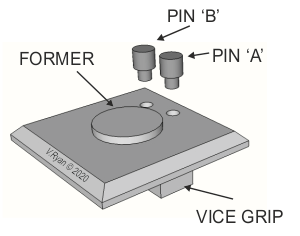

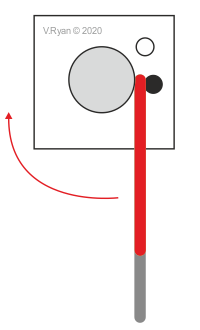

The jig is manufactured from mild steel and is composed of the circular part called the former. Two pins are also needed.

Pin ‘A’ holds the steel rod in place whilst it is forced round the circular former.

Pin ‘B’ holds the rod in the second position whilst the rod is forced form its final shape.

PLEASE NOTE: When the steel is heated in the forge to red heat, it expands. Consequently, it is important to allow for this expansion, when making the jig. If the steel fits into the jig tightly, when it is cold, it will not fit when it has been heated. |

| |

|

|

|

|

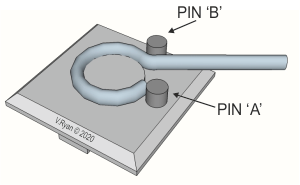

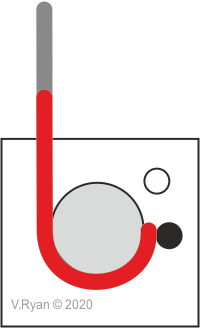

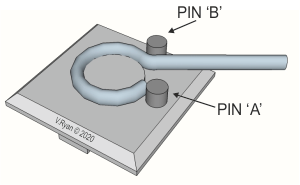

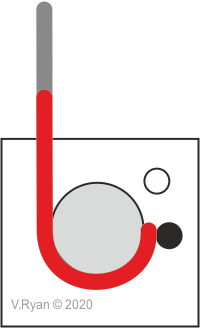

The diagram opposite shows how the ‘eye’ will look, when it is formed in the jig / former |

| |

|

|

|

|

| |

|

|

| STAGES OF FORGING USING A JIG / FORMER |

| |

|

|

The round section steel rod is cut to length. |

| |

|

|

|

|

The ends of the steel rod are filed using a hand file. This removes any burrs and sharp edges.

Alternatively, a centre lathe can be used to ‘face off’ the ends. |

| |

|

|

|

|

| |

|

|

|

|

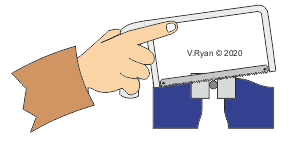

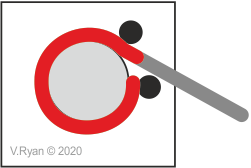

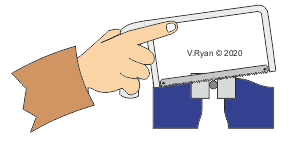

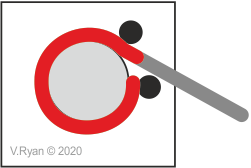

Pin ‘A’ is used to hold the steel rod in position in preparation for applying pressure to it. Pin ‘B’ is not positioned in the block at this stage. The area to be formed into an eye is heated in th forge to red heat. |

| |

|

|

|

|

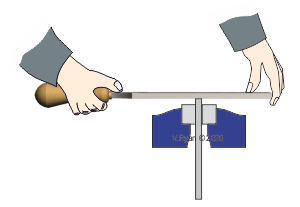

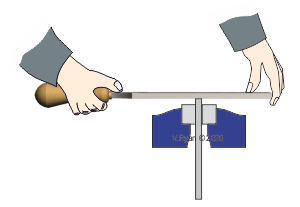

Hand pressure is applied to the steel rod and it is forced around the former, producing an accurate curve. Pin ‘B’ is still not positioned in the jig. Care must be taken, as the metal is being forged at a very high temperature. |

| |

|

|

|

|

| |

|

|

|

|

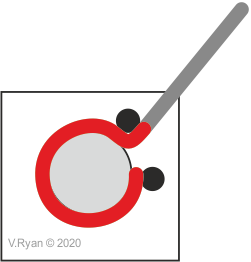

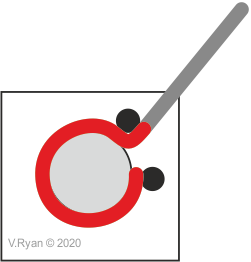

The steel rod is forced round the former, until it passes the position of pin ‘B’. Pin ‘B’ is then inserted in the jig. |

| |

|

|

|

|

The rod is then forced into its final position, forming an accurate eye and it is allowed to cool, by placing it on the face of an anvil or it is quenched. |

| |

| |

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|