V.Ryan © 2020

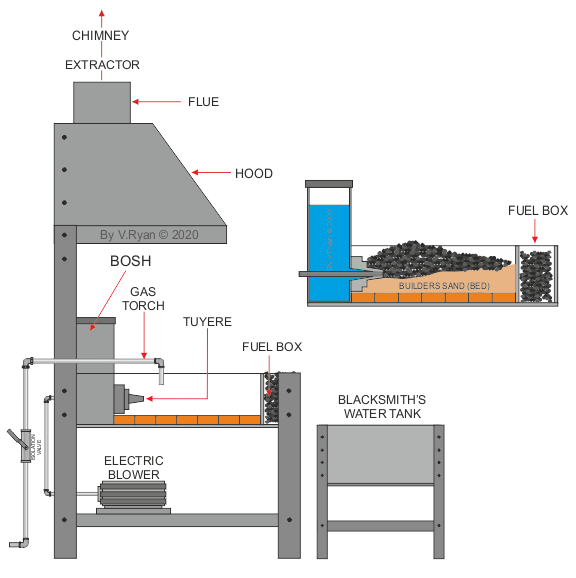

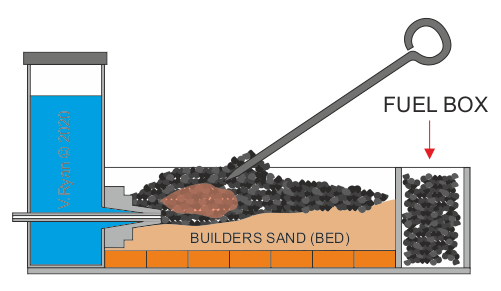

The Blacksmith’s Hearth is essential for any forgework to take place. Traditional hearths, such as the one seen below, are manufactured from either mild steel or cast steel. Mild steel hearths require a fire brick lining. Both types of hearth need a ‘bed’, built up from builders sand. The fuel is placed on top of the sand (Blacksmith’s Breeze, sometimes referred to as ‘Coke Beans’ or Smithy Coal).

This type of fuel, ensures optimal performance of the hearth, allowing high temperatures to be reached and controlled. Spare fuel is stored in the ‘fuel box’, at the front of the hearth, where it can dry and warm before it is used. Never use damp fuel in the hearth, as it has the potential to ‘spit’ wildly, which is dangerous. Inevitably, the fuel will be used up, through the heating process and it generally forms a ‘clinker’ (waste) near ‘tuyere’, which can be removed in one piece.

The hood of the hearth directs the fumes towards the flue, where an extractor fan takes over.

A Blacksmith’s water tank is placed close to the hearth, often in front of it. This allows metals to be quenched quickly, and also Blacksmith’s tools. An electric blower provides the ‘blast’ through the tuyere and is used to control the burning fuel and the temperatures required for blacksmith’s various processes.

A blast of air goes through the tuyere, feeding the fire with the oxygen it needs for high temperatures. The amount of air passing through the tuyere, can be controlled and completely stopped if necessary. Most tuyeres are protected by a jacket of water, stored in the BOSH. The water protects the tuyere from damaged caused by being exposed to very high temperatures, during prolonged periods of forging.

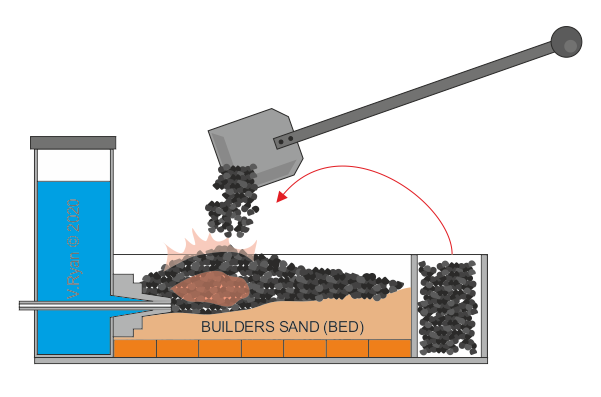

USE OF THE SLICE

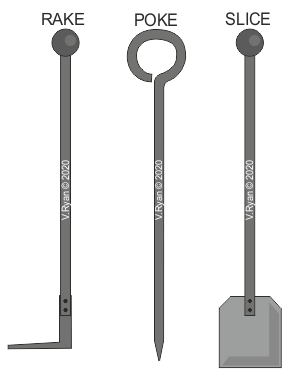

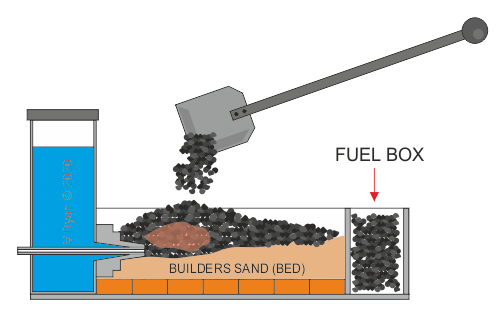

The slice is used to add coke to the ‘heart’ of the fire in the hearth. The coke is taken from the fuel box, where is has been preheated and dried before adding to the hearth.

USE OF THE RAKE

The rake is used by the Blacksmith to reposition the coke and to remove any ‘spent’ fuel and clinker. This helps to keep the fire in a healthy state, building up heat/temperature.

USE OF THE POKE

The Blacksmith uses the poke to move coke pieces out of the way, allowing air to penetrate and feed the heart of the fire. Usually, the poke is used along with the rake.

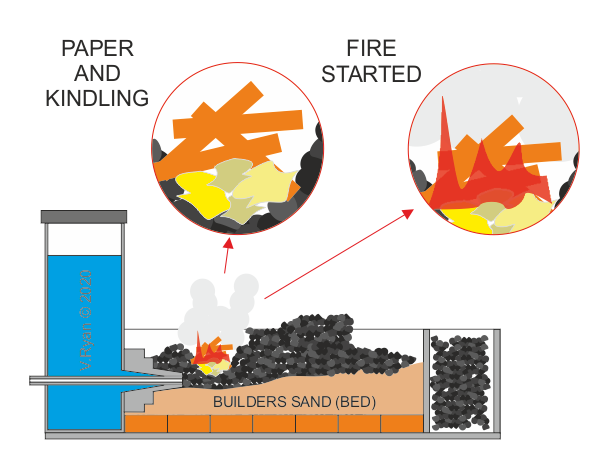

LIGHTING THE FORGE

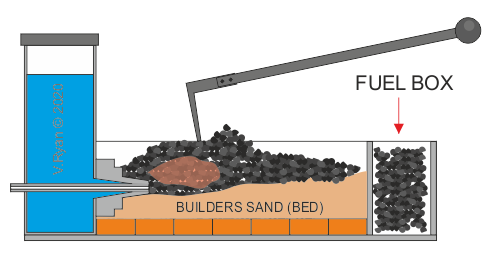

Lighting the forge is relatively straightforward. A small hollow / depression is formed in the coke, in front of the tuyere. ‘Rolled up’ newspaper, with a few pieces of kindling (wood), are placed in the hollow and the paper set alight. As the fire takes hold and begins to ‘grow’ in intensity, a small amount of coke is added to the ‘fire’ and a gentle blast of air delivered through the tuyere.

MAINTAINING THE FIRE

Coke is added as the fire grows in intensity and the air blast is controlled to ensure just enough air is ‘blown’, to encourage the fire. Too much power in the blast, could at this early stage, blow out the fire.

The coke is eventually heaped carefully above the heart of the fire. Usually, only a small proportion of the hearth is required for forging and it is located just in front of the tuyere.