V.Ryan © 2020

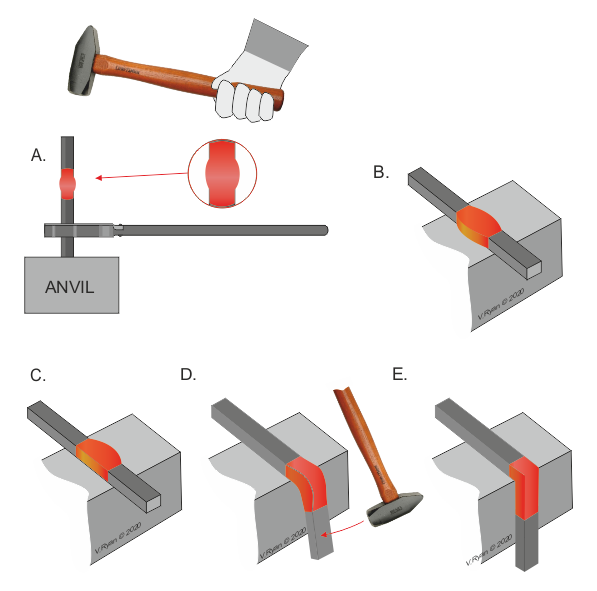

Basic bending / folding of steel, begins with heating the metal to ‘cherry red’. The metal is placed on the anvil and it is hammered to shape, as seen in the diagram. A chalk line should be drawn on the metal, before heating, which marks the point of the bend. The aim should be to limit the hammer strikes, keeping them to the minimum. This helps to protect the metal, reducing the risk of deformation.

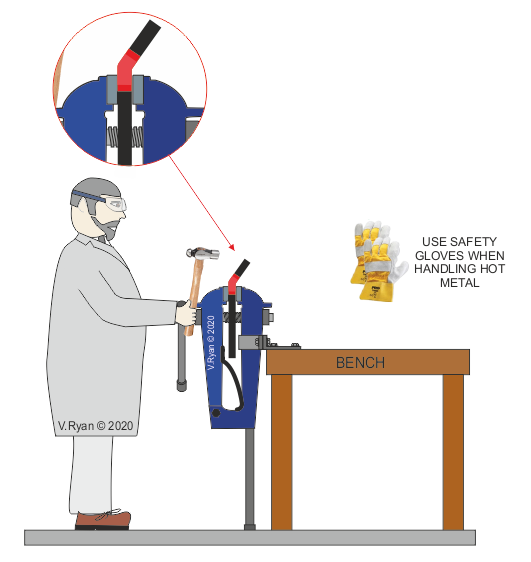

USING A LEG VICE TO HELP FORM A BEND

The leg vice is used here, to hold a substantial piece of steel, ready for forming to a 90 degree angle. The steel has been heated to ‘red heat’, on a brazing hearth or in a forge, so that it is malleable and can be formed more easily. The long piece of steel fits between the jaws of the leg vice, without interference from the bench, giving plenty of room. The heavy blows to the steel, from the ‘large’ ball pein hammer, will not damage this type of vice, but they could damage an engineers vice.

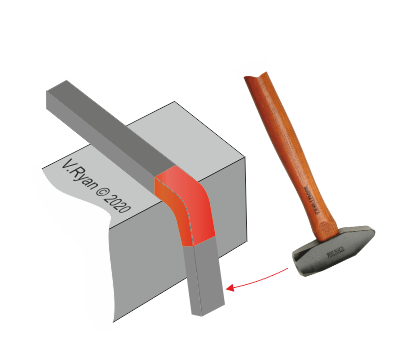

For an accurate 90 degree bend, there is a more detailed process. The metal is ‘upset’ in the area of the bend (dia A.). The metal is then placed down on the anvil face, were the upset area is flattened (dia B.). Eventually, the three sides of the upset area are fattened, leaving a ‘bulge’ on one side (dia C.) The bend is then forged slowly, over the edge of the anvil (dia D.) As the bend is formed, the ‘bulge’ is hammered out and a precise bend is formed.