|

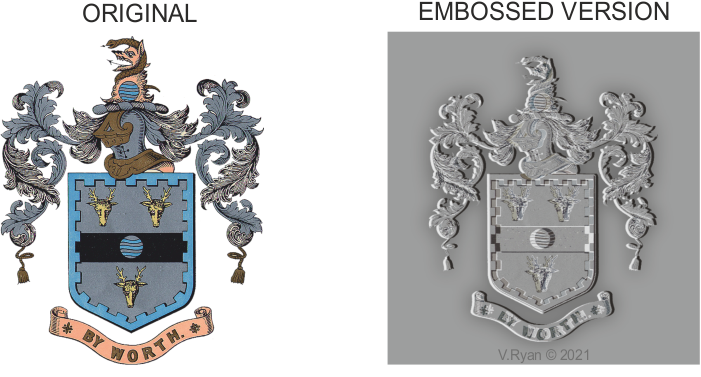

Embossing involves raising areas of a card surface above the level of the rest. The diagram below shows a coat of arms that has been embossed on grey card. The images stands out from the card as it has been produced by a stamp which presses the card to the correct shape. This process adds cost to the printing process, but gives the card a 3D effect. |

|

|

|

|

|

|

|

|

|

|

Alongside the embossed version is the same coat of arms printed in colour, on paper - note the difference. Embossing usually doubles the cost of normal printing, as it takes place after processes such as colour, printing and varnishing have been completed. |

|

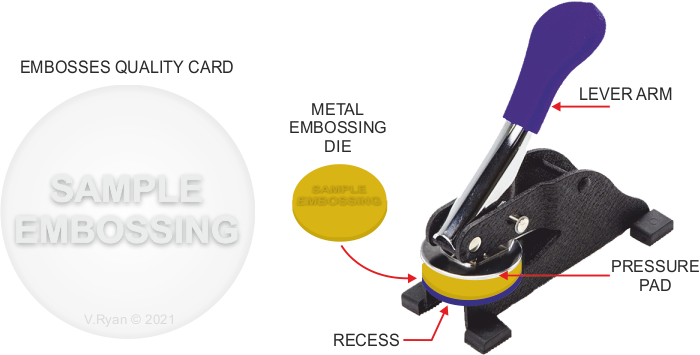

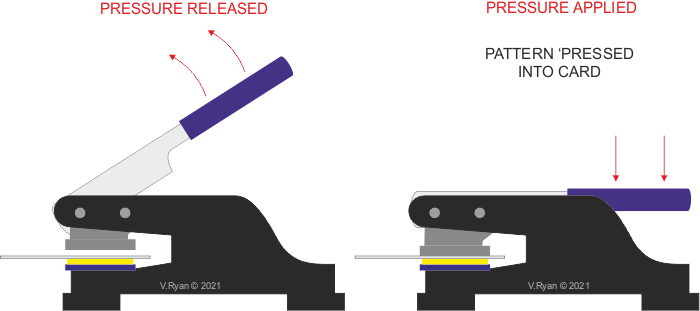

| Hand Embossing Presses, can be used to imprint paper, card and metal foil, with patterns, crests, symbols and even words. To operate the press, a metal embossing die (with the desired pattern), is placed into the recess below the pressure pad. The paper / card is placed between the embossing die and the pressure pad. Hand pressure is then applied, forcing the die into the paper / card. This leaves a permanent impression, in the paper / card. Metal foil blanks are ideal for this type of embossing process. | |

|

|

|

|

|

|

| ALUMINIUM FOIL BLANKS ON A ROLL | |

|

|

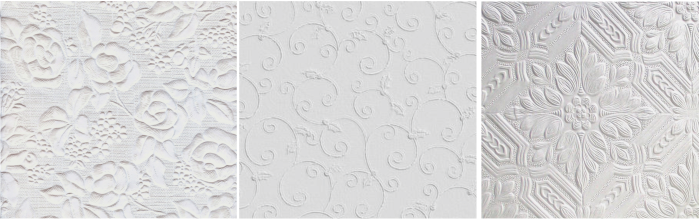

| Some expensive, upmarket wall paper is embossed. This is achieved by sending quality paper through textured rollers, which leave their pattern pressed into the paper. Click here for further information. | |

|

|

|

|

|

|

QUESTIONS: |

|

|

SIMPLE EMBOSSING |

|

|

A good example of simple embossing can be seen below. A letter with a coat of arms is to be sent to a number of important people. To make the letter look and feel more important the coat of arms is to be embossed. This means that the coat of arms must stand out from the surface of the card / special paper. |

|

|

A special embossing tool has been made with the shape of the coat of arms engraved on its base. The embossing tool is aligned with the printed coat of arms and the mallet is then used to strongly tap the embossing tool. The material underneath the letter is rubber so that the ‘blow’ from the mallet / embossing tool is absorbed and yet allows the embossed area of the paper to stand out from the rest of the papers surface. |

|

|

During the use of the embossing tool, the paper is reversed so that the blow is to the back of the crest of arms. |

|

|

|

|

|

If many copies of the same embossed paper was needed, automatic printing machines can be used. These will print the coat of arms and any text and then emboss the specified area. Thousands of copies can be produced accurately. |

|

|

QUESTIONS: With the aid of diagrams, describe how a card embossed shape is created. (for example, a crest of arms on a letter headed piece of note paper. |

|

|

|

|