| CLICK HERE FOR INDEX PAGE |

| |

| SELF-HEALING MATERIALS - POLYMERS, ELASTOMERS AND CONCRETE |

V.Ryan © 2019 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

This is a category of smart materials and are materials that are designed to be self-healing. They have been developed to repair damage to their micro-structure. This is why some of these materials are called ‘smart structures’. One obvious advantage, is that human intervention is not required. Self-healing materials also reduce the number of diagnostic checks required by a skilled technician or computer controlled sensors. The ability of a material to self-heal, extends its useful, working life time.

Although self-healing of materials have some advantages, the resulting repair, may reduce the materials ability to conduct electricity, heat, flex and even impair the materials acoustic properties, such as the ability to insulate sound. |

| |

A range of materials are classified as self-healing.

Some polymers have micro-encaspulated resin, that is released into a damaged / cracked area, effectively healing the area. The resin is ‘infused’ through a network of cross-linked polymer chains, providing the self-healing capability. Healing can take place at low temperatures and the age of the material does not unduly, effect the healing process. |

| |

|

|

| |

| SELF-HEALING - POLYMERS AND ELASTOMERS |

| |

| The diagram below, shows the process of self-healing, by some polymers and elastomers. |

| |

|

| |

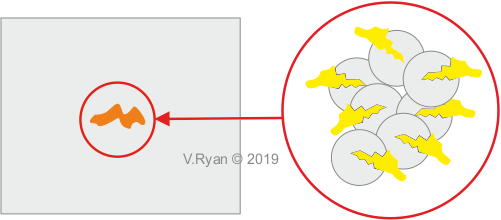

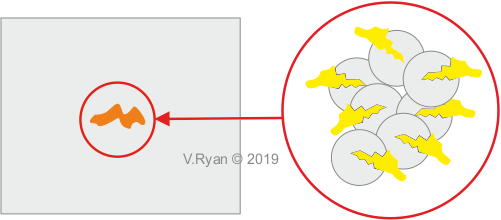

| The diagram below, shows two long chain polymer molecules. The damaged area (a crack in the material) has been ‘healed’ through cross-linking. The cross linking, provides a bond between the two long chain polymers. The cross linking has been achieved through the release of a micro-encaspulated resin, after the crack in the material occurred. |

| |

|

| |

|

|

| |

| PRACTICAL EXAMPLES |

| |

| SELF-HEALING POLYMERS |

| Self-healing polymer coating can be applied to metals, as a spray. In the event of corrosion occurring on the metals surface, corrosion inhibitors are released in the area affected, from micro-capsules. This can occur at a nano level. |

| |

| |

|

|

An area of the metal begins to display signs of corrosion. The healing process is triggered and the polymer coating, releases corrosion inhibitors from its micro-capsules. |

| |

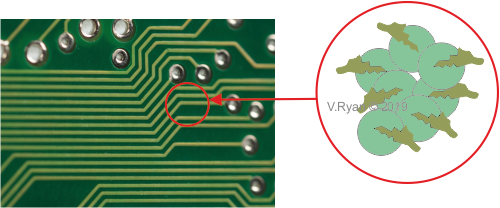

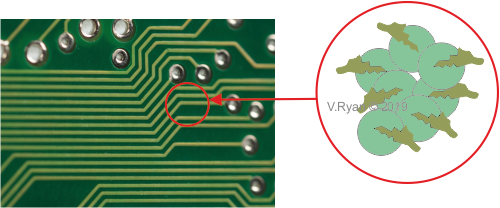

| In a circuit, if the copper track is damaged at a micro level, this prevents electrical conduction. The polymer coating releases ‘Intrinsically Conducting Polymer’ (ICP), from micro-capsules. This ‘heals’ the copper track, allowing electricity to be conducted. |

| |

| |

|

|

A track of the circuit ‘cracks’. The healing process is triggered and the polymer coating releases a liquid / resin, conducting polymer, from micro capsules. The resin hardens and heals the crack, allowing electrical current to pass through it and the circuit continues to function. |

| |

|

|

| |

| SELF-HEALING CONCRETE |

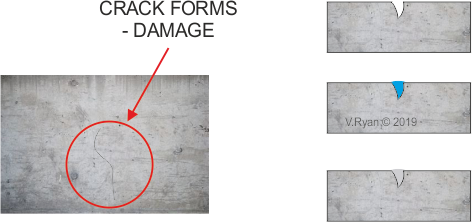

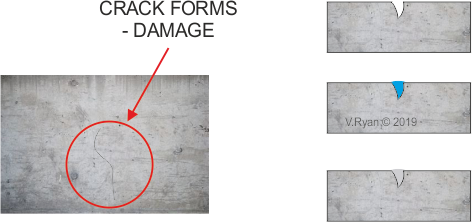

Self-healing concrete (also called bio-concrete), is a material that heals itself, if cracks or minor damage occurs. Concrete is one of the worlds most widely used materials. When a human bone is damaged, it is repaired through a natural process, whereby calcium forms around the damaged area, repairing the bone. A similar process takes place, when self-healing concrete is damaged. A process of mineralisation takes place.

How it works: When the concrete ‘cracks’, water enters the crack and reacts with bacteria, which is found in the limestone, one of the constituent parts of concrete. The reaction results in the formation of more limestone, repairing the crack. |

| |

|

|

Crack forms - damage.

Water initiates healing process. The bacteria feed on calcium lactate, forming new limestone.

The crack is healed, with the new limestone |

| |

| |

| |

| CLICK HERE FOR MATERIALS INDEX PAGE |

| |

|

| |

|