| |

| CLICK HERE FOR INDEX PAGE |

| |

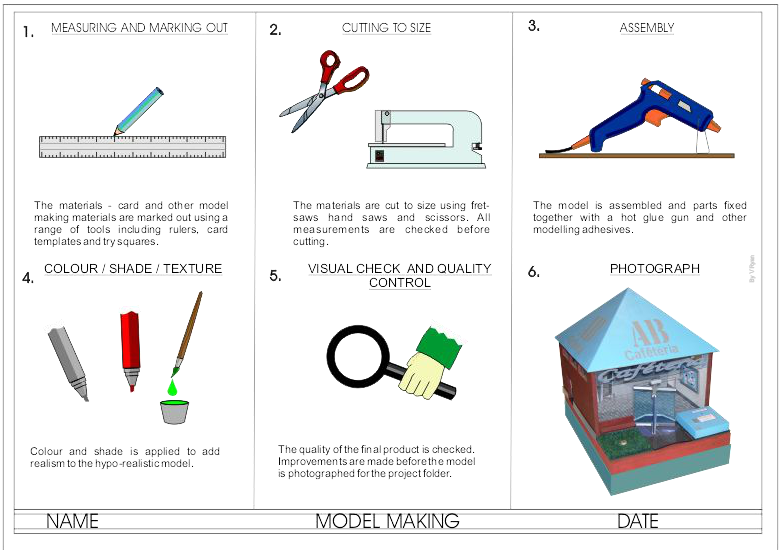

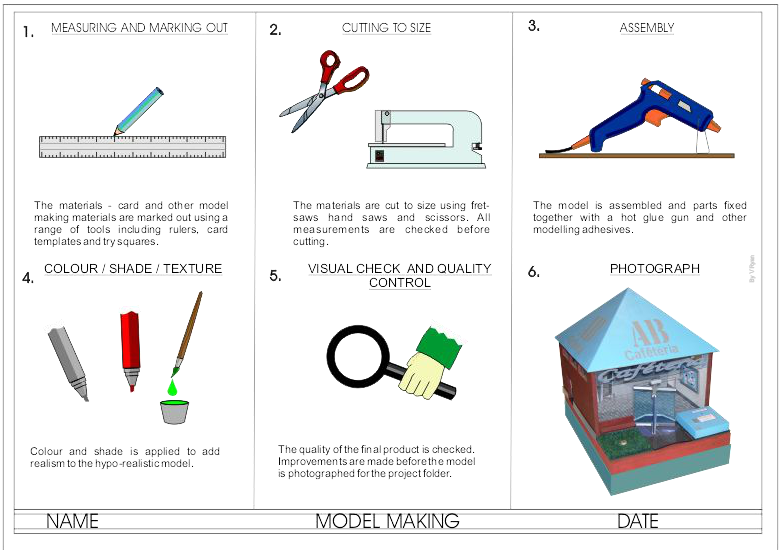

| MODEL MAKING |

| V. Ryan © 2008 - 2010 |

| |

|

PDF FILE -

CLICK HERE FOR MODEL TEMPLATE SHEETS |

|

|

|

When designing a product there is a time when it is

necessary to make a scaled model. This is a useful exercise as it allows

the designer to select an idea and make a 3D representation.

Usually a designer will make a number of models starting with quick card

models progressing to more detailed scaled models manufactured from more

expensive materials. Sometimes specialised modelling materials are used to

produce hyper realistic models. Making a model or range of models is

regarded as good industrial practice. |

|

The model cafeteria below has been manufactured from a

range of model making materials. It has been fitted with four temperature

sensors. They have installed to detect fire as the temperature will rise

quickly when a fire takes hold. This is a working model and can be tested

/ evaluated. Improvements can then be implemented for the final design and

product. |

| |

|

|

|

| |

|

|

1. Making a model allows the designer to physically see

the idea in 3D form.

2. It helps the designer identify potential faults and correct them as

well as make further improvements.

3. It allows the designer to experiment with a range of materials,

eventually selecting the best materials for the chosen design. Sometimes

it is a good idea to make a selection of models from a range of materials.

This allows the designer to experiment before purchasing expensive

materials for the actual manufactured product.

4. It allows a simple evaluation of the design by the designer and

potential customers.

5. It is easier to record the views of others by showing them a 3D scaled

model rather than a ‘flat 2D’ drawing.

6. A 3D model can be passed around a table of people who form a customer

focus group.

MAKING A COMPUTER MODEL

1. A computer model can be as useful as a 3D model made from actual

materials. A CAD drawing can be revolved, sectioned and viewed in a

variety of ways.

2. Computer models allow the designer to apply colour and texture very

easily change the very nature of the product in seconds.

3. If a potential client is viewing the computer model it can be changed

and updated at the time of the meeting / interview.

4. A disadvantage of a computer model is that a computer and software are

required.

5. Computer software can be used to calculate the cost of the finished

product. For example, crocodile clips software can be used to calculate

the cost of components required for a completed circuit. Most CAD software

can be used to calculate the volume of materials needed. This means that a

project can be costed early in the design process.

6. Spreadsheets can be used to calculate the cost of projects and this is

an essential part of project work. Spreadsheets can also be used to model

situations and are especially useful for systems and control projects. For

instance, spreadsheets can be used to stimulated temperature change within

a systems environment.

7. Flow charting software such as that used in crocodile technology allows

the programming of a PIC Microcontroller circuit to be stimulated, tested

and improved. |

| |

|

|

| |

|

The computer generated model of a simple folding chair

has been produced using CAD (Computer Aided Design software). It allows

the designer to rotate the model and to zoom in on any aspect of the

design. |

|

| |

| Produce a sequence drawing that clearly shows

the manufacturing of the realistic model. |

| |

|

| |

|

|

| |

|

Evaluate the model. The model could be shown to

potential customers and suggestions for improvements recorded. A sample

evaluation sheet is shown below. |

| |

|

| |

|

|

| |

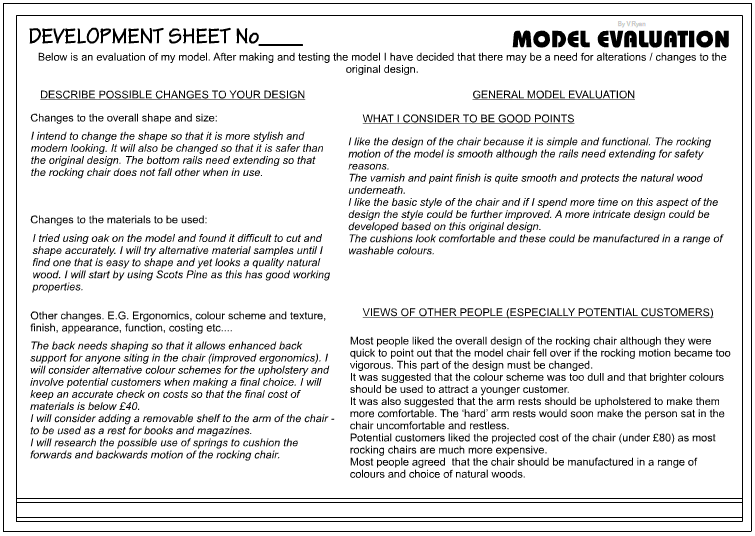

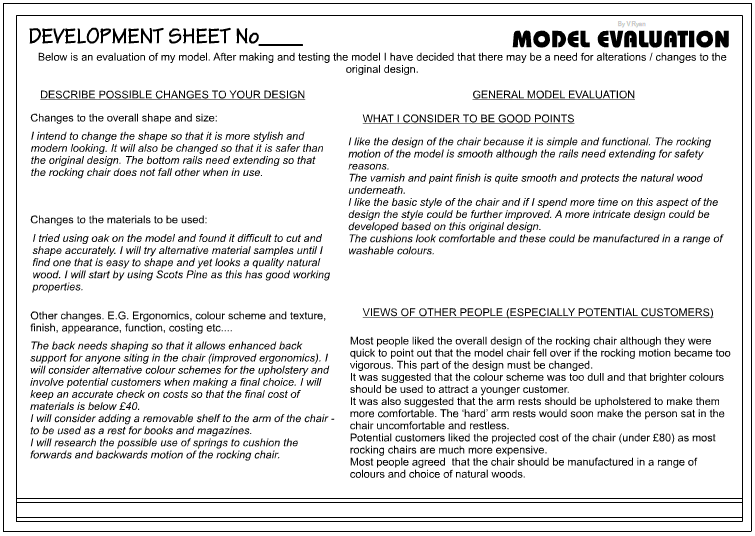

| The sample model evaluation seen below has

been written for a model of rocking chair. |

| |

|

|

|

|

|

|

CLICK HERE FOR DESIGN PROCESS INDEX

PAGE |

| |

|