| CLICK HERE FOR INDEX PAGE | |

| FOUNDRY WORK (1) | |

| V. Ryan © 2003 - 2022 | |

|

A specialised part of the manufacturing/engineering world is casting or foundry work as it is properly called. In schools and colleges this usually involves casting molten aluminium. Before any casting can take place a wooden pattern is made precisely. This is called pattern making and in industry this is a very skilful job. Any inaccuracy at this stage will result in the final cast being wrong or even failing. In schools the pattern is usually made from a softwood and its sides are given a draft (an angle) so that it can be removed from the sand easily. |

|

| THE CASTING BOXES (COPE AND DRAG) | |

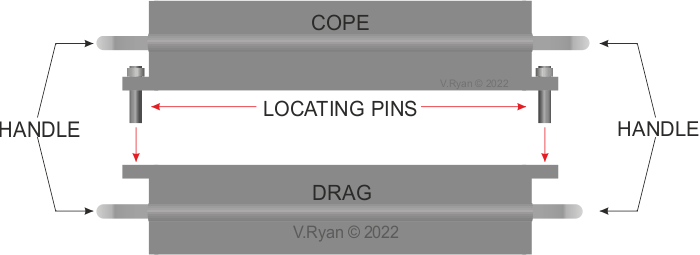

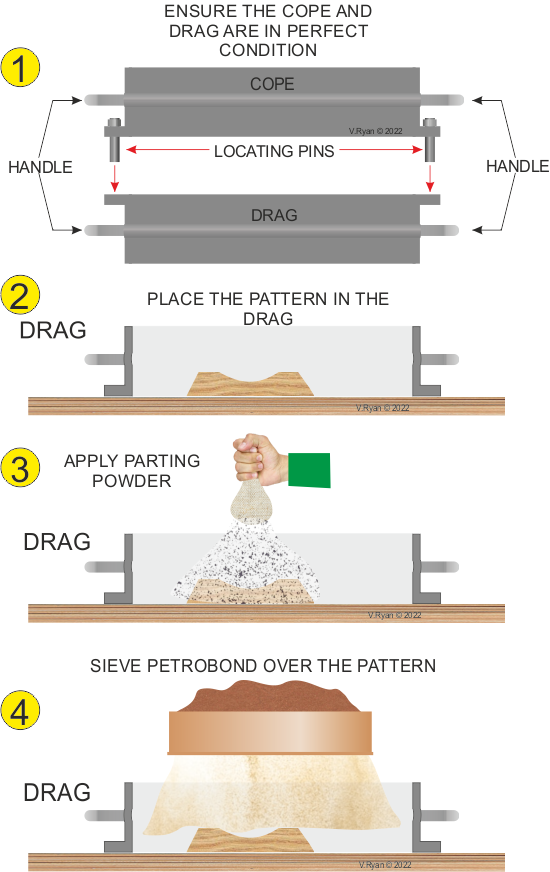

| The casting boxes are known as the Cope (top box) and the Drag (bottom box). They should be inspected before use, to ensure that they are in good condition. | |

|

|

| THE PROCEDURE - FIRST THREE STAGES | |

|

|

The diagrams to the left shows the pattern on a flat board and a casting box called a ‘drag’ being placed over it. |

|

|

Special casting sand will soon be packed around the pattern but to ensure to can be removed easily from the sand, parting powder is sprinkled over and around it. (parting powder is similar to talcum powder). It stops the casting sand sticking to the pattern and pulling away with it when the pattern is finally removed from the sand. |

|

|

Casting sand is then shaken through a sieve (called

riddled sand) so that only fine particles fall around the pattern. This

is called facing sand and it must be fine so that detail on the pattern

shows up on the final casting. |

| SUMMARY OF FIRST FOUR STAGES | |

|

|

|

|

|