| CLICK HERE FOR INDEX PAGE | |

| MOULDING THROUGH COMPRESSION | |

| V. Ryan © 2002 - 2021 | |

| Compression Moulding - Box Learning Exercise (Independent Learning Exercise) | |

|

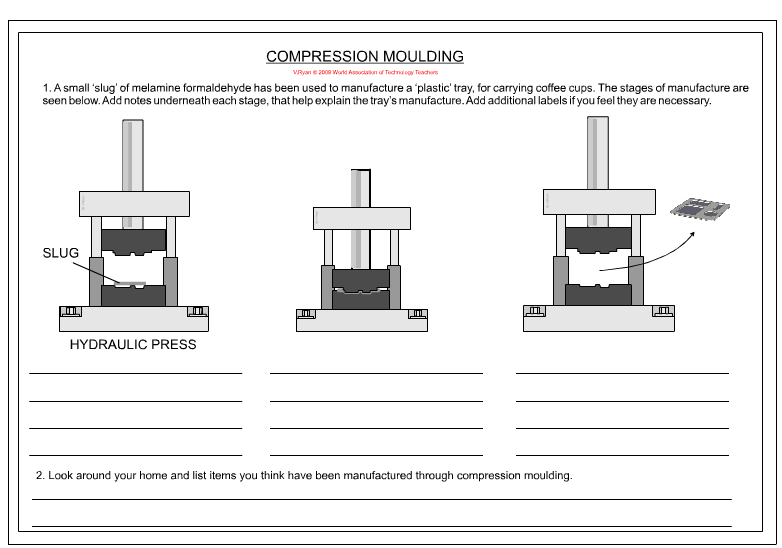

Moulding through the force of compression is another very common industrial process. The materials used are melamine formaldehyde, phenol and urea. These materials can be formed into different shapes through applying both heat and pressure, other plastics do no have these properties. |

|

|

|

|

| The stages are as follows:

1. The mould is heated. 2. A 'slug' or piece of the selected plastic is placed into the mould and warms up. 3. The hydraulic press begins to move down when the plastic has reached the correct temperature.. 4. As the upper and lower mould meet, the plastic is compressed into the shape of the mould. 5. The upper mould moves upwards and the plastic piece (in this case a tray) is removed. |

|

|

Look around your home and list items you think have been manufactured through compression moulding. |

|

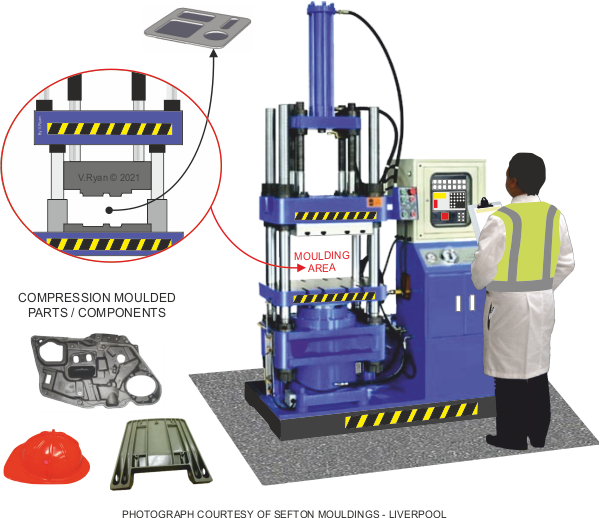

| INDDUSTRIAL APPLICATION OF COMPRESSION MOULDING | |

|

|

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET SHOWN BELOW | |

|

|

| CLICK HERE FOR MORE ON COMPRESSION MOULDING | |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX | |

|

|

|