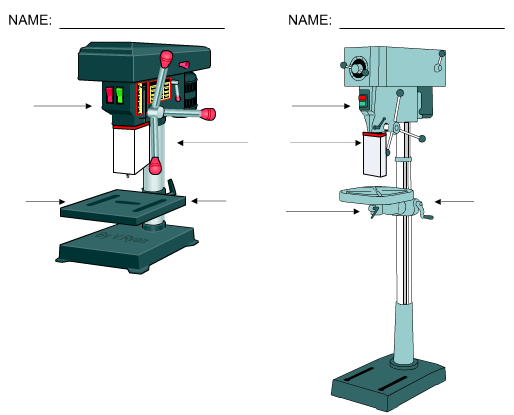

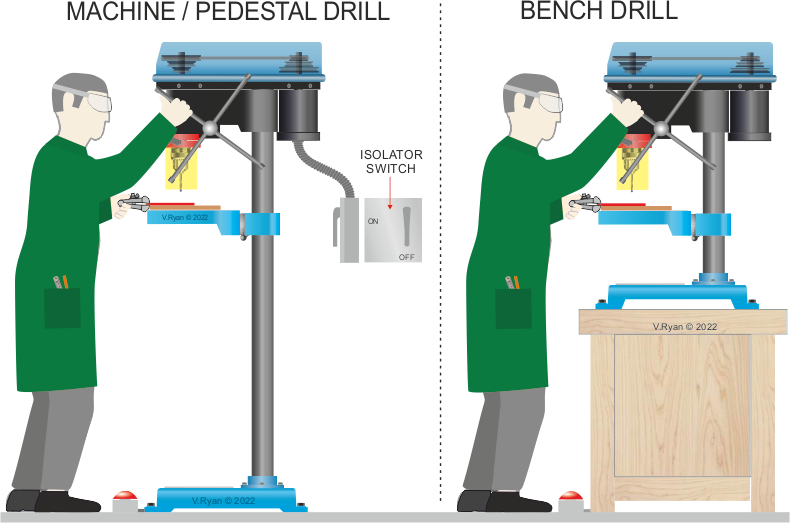

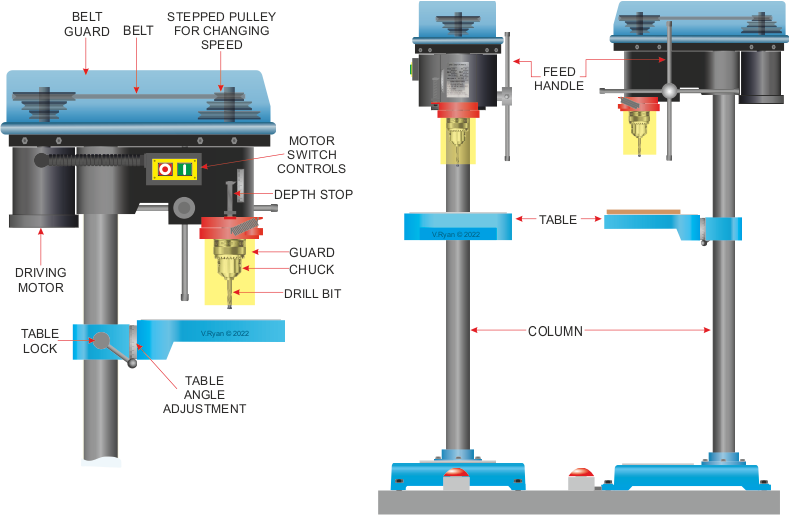

The larger version of the machine drill is called the pillar drill. This has a long column which stands on the floor. This can do exactly the same work as the bench drill but because of its larger size it is capable of being used to drill larger pieces of materials and produce larger holes.

SAFETY

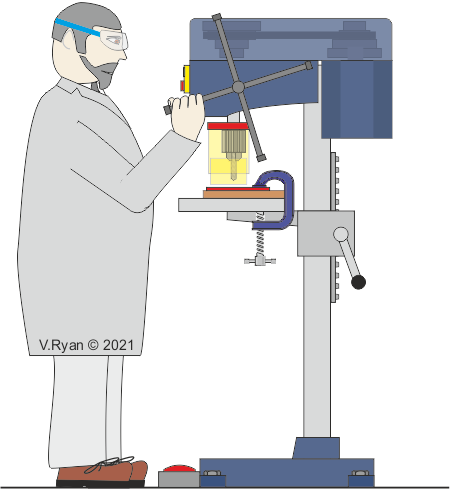

1. Always follow the instructions given by your teacher. (only use the machine if you have permission and have been trained to use it).

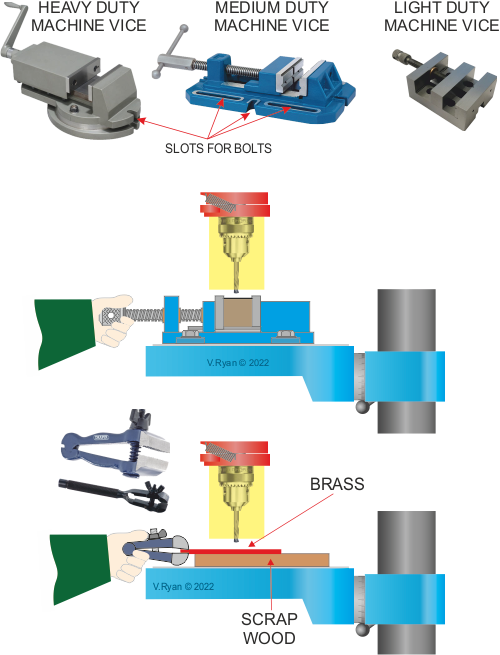

2. Clamp the work down, do not hold the work in your hand.

3. Use the guard.

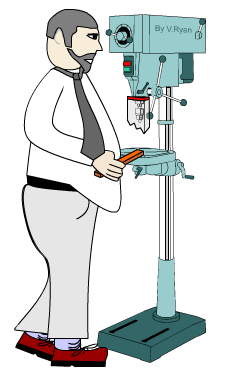

4. Wear safety clothing and footwear.

5. Tie back long hair or use a hair net.

6. Only one person at a time, to use the drilling machine.

7. Do not distract the person operating the drill

2. List safety factors regarding the use of the drilling machines.

3. Demonstrate the use of the bench/pillar drill to a group of pupils, emphasising safety.

The height of the table is set by adjusting the table handle (see below). When drilling, the table should be moved quite close the the drill bit, so that the distance from the drill bit to the material is small.

Some machine drills have a rack and pinion system that allows height adjustment. The rack and pinion table adjustment, allows the user to lower or higher the machine table with ease. Simply rotate the handle to move the machine table up or down. Rotating the handle, rotates the worm gear. The worm gear meshes with the pinion gear, which rotates. The pinion gear meshes with the rack, moving the machine table either up or down.

The machine table is then locked in position.

The guard should always be used. This is the first line of defence if the material being drilled breaks or shatters. Wearing goggles is the second line of defence.