| CLICK HERE FOR INDEX PAGE | |

| THE CENTRE LATHE - 'FACING OFF' | |

| V. Ryan © 2003 - 2021 | |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

|

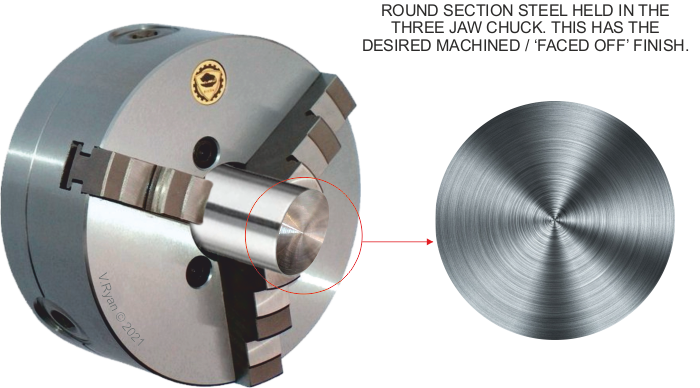

A very basic operation is called ‘facing off’. A piece of steel has been placed in the chuck and the lathe cutting tool is used to level the end. This is done by turning the cross-slide handle so that the cross-slide moves and the cutting tool cuts the surface of the steel. |

|

|

|

|

Only a small amount of material should be removed -

each pass of the cross slide. After each pass of the cutting tool the

top slide can be rotated clockwise to move the tool forward

approximately 1mm. This sequence is repeated until the steel has been

levelled (faced off). |

|

|

|

|

TURNING A SHORT TAPER

When turning a short taper the topslide is set a the required angle.

This is normally done by loosening two small allen screws and then

rotating the topslide to the angle and tightening back up the two allen

screws. |

|

|

|

|

QUESTIONS: 1. Explain the term 'facing off'. Use diagrams and notes. 2. Using diagrams explain how a short taper can be turned using the centre lathe. |

|

|

|

|