| CLICK HERE FOR INDEX PAGE | |

| TURNING A LONG TAPER | |

| V. Ryan © 2003 - 2021 | |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

|

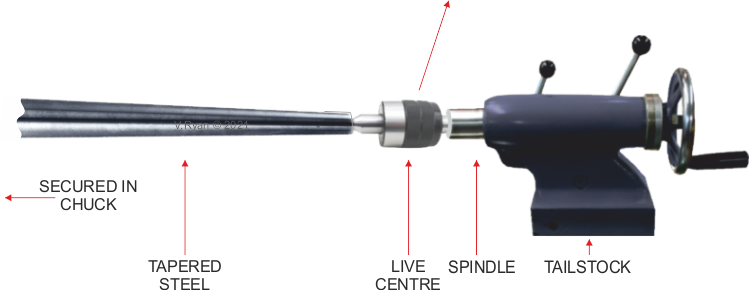

Turning a taper on a long piece of material is best achieved by offsetting the tailstock. The material is held between two centres as a normal three jaw chuck cannot be used. A three jaw chuck will not hold the material safely or accurately when a long taper is being turned. Diagram ‘A’ below shows the side view of the two centres, the material and the toolpost. |

|

|

|

|

|

|

| In this example, a Live Centre has been ‘set up’ in the spindle of the tailstock. The advantage is this type of centre, is that it revolves freely, unlike a dead centre, which requires regular greasing, to reduce friction. |  |

|

|

|

Diagram ‘B’ shows a birds eye view (plan view) of the same equipment. However, this time it can be seen that the tailstock has been adjusted so that it is off centre. This means that a long taper can be turned. A small amount of material must be removed with each pass of the cutting tool. Also the lathe should be setup so that the cutting tool feeds automatically along the bed of the lathe. This will lead to a better finish to the surface of the material. The animation below shows a 'speeded up version' of taper turning. Normally taper turning takes along time. |

|

|

|

|

|

|

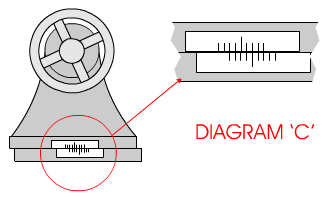

Diagram ‘C’ shows the scale at the back of the tailstock. To adjust the tailstock so that it is off centre usually means loosening a number of allen screws, offsetting the tailstock and then tightening the screws back in position. |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE | |

|

|

|