| CLICK HERE FOR INDEX PAGE | |

| WOODTURNING TOOLS - GOUGES | |

| V. Ryan © 2012 | |

|

A large range of lathe turning tools are available,

allowing different types of cutting and shaping. The handles of turning

tools are ‘substantial’, as they are securely held by the lathe operator,

when in use. Leverage is often needed to ensure safe and correct use of

the lathe tools. The long turned handles of lathe tools, are comfortable

to hold and use. |

|

| ROUGHING OUT GOUGE | |

| A roughing out gouge is used to remove the majority of wood when turning. It is useful in the initial stages of wood turning. Other tools are used to produce a more accurate finish. | |

|

|

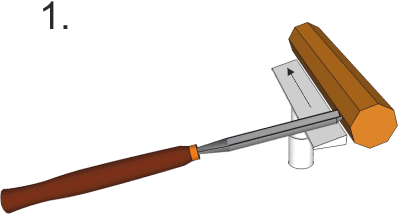

| Diagram 1 shows a roughing out tool being used, to produce a cylinder of natural wood. Further detail is then added with other lathe tools. | |

| The tool rest should be quite close to the wood. Before turning on the lathe, spin the wood by hand to ensure that it does not ‘catch’ on the tool rest. |

|

|

|

| SPINDLE GOUGE | |

| Spindle gouges are also used for roughing out material, but in ‘tighter’ / smaller areas. | |

|

|

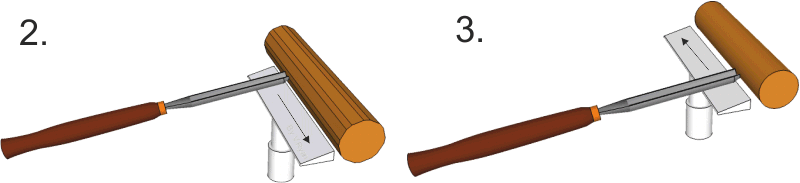

| BOWL GOUGE | |

| A bowl gouge has a deeper flute than a standard roughing out gouge. Consequently, it can be used to remove material more rapidly and is particularly useful for turning hollows, when turning bowls and similar depths. | |

|

|

| A bowl gouge is used to produce the internal shape of a bowl. The plain T-rest is replaced with a bowl turners lathe tool rest. This allows the wood turner to support the gouge / scraper, when turning the internal shape. |

|

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE | |