| CLICK HERE FOR INDEX PAGE |

| GENERAL MATERIALS - QUESTIONS AND ANSWERS |

| V. Ryan © 2010 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

|

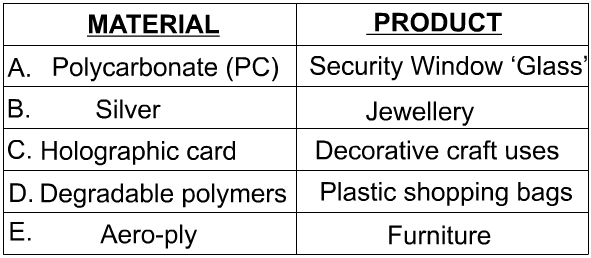

1. A range of products and the materials from which

they are manufactured, are listed below. Explain/describe why each

material has been selected for corresponding product. |

|

|

A. Polycarbonate is ideal for

replacement security windows, as it is impact resistant . If a burgular /

vandal attempts to break into a property, by breaking the window with a

brick/rock, it will simply bounce off. The polycarbonate is transparent and although it can be scratched, it still allows maximum sunlight through it, into the interior of a building. It is lightweight and can be handled more vigorously than traditional glass. If dropped, it will absorb the impact and flex, rather than shattering. |

|

B. Silver is a valuable,

precious metal and has been used in the manufacture of jewellery for

thousands of years. As a rare / valuable metal, customers automatically

appreciate its precious nature. A variety of manufacturing techniques can be used when working with silver. These include, small scale casting and beaten metal working techniques, resulting in complex shapes. It can be soldered and joined. When polished, it shines brightly as expected of an attractive, valuable metal. |

|

C. Holographic card can be

used in the manufacture of a range of decorative and craft products. Hand

made holographic birthday cards is one example, gift tags being another. Metallised silver card is excellent for bright posters, cut out toys,

boxes, and display boards. It has a 3 dimensional visual affect, reflecting light. It can be shaped, scored and formed with scissors. It can be folded to produce into boxes. |

|

D. Degradable polymers such

as ecofilm, dissolve over time, producing water and carbon dioxide. This

means it does not pose an environmental threat. Shopping bags manufactured

from this material degrade quickly, when discarded, melting away over a

small number of weeks. Degradable shopping bags are as strong as standard supermarket shopping bags, holding the same load, securely. Degradable plastic shopping bags are manufactured in the same way as a typical polythene bag and can be plastic welded. Degradable shopping bags are thin film products, just as polythene shopping/carrier bags. |

|

E. Aeroply is ideal of

producing curves and irregular shapes and forms. Layers of aeroply are

glued together whilst being securely held on to a former/mould. This is

typical of laminating. Aeroply gives the opportunity to form unusually curved shapes that cannot be manufactured using any other material, to the same high standard. Aesthetically pleasing shapes can be the result. Aeroply can be painted or stained. It can be glued with normal wood glues such as woodworkers resin / PVA. |

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE |