| CLICK HERE FOR INDEX PAGE | |

| WHAT IS KEVLAR? TYPES OF KEVLAR | |

| V. Ryan © 2011 | |

|

|

Kevlar® is a material formed by combining para-phenylenediamine and terephthaloyl chloride. Aromatic polyamide (aramid) threads are the result. They are further refined, by dissolving the threads and spinning them into regular fibres. When woven, Kevlar® forms a strong and flexible material. If layers of the woven Kevlar® are combined with layers of resin, the resulting ‘rigid’ material is light and has twenty times the strength of steel. It is also superior to specialist metal alloys. However, Kevlar® is expensive due to the demands of the manufacturing process and the need for specialist equipment. |

KEVLAR, KEVLAR 29 AND KEVLAR 49 |

|

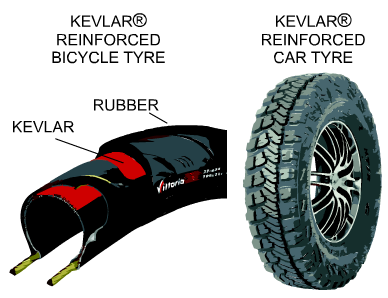

| There are three main

types of Kevlar®. 1. Kevlar® is used as a reinforcement material for some car tyres and bicycle tyres. It helps dramatically reduce puncture rates. This standard of tyre is more expensive than ordinary road tyres. They are of particular use with 4 x 4 vehicles, especially when the vehicle is being used off road and far away from recovery services. |

|

| 2. Kevlar® 29

is used in the manufacture of body armour (panels) for lightweight

military vehicles. A good example is the US Army’s ‘Bradley Fighting

Vehicle’. This has been used extensively in Iraq and Afghanistan. Kevlar®

29 was selected for its armour, because it is lightweight and withstands

attack from RPGs. The Kevlar® 29 panels protect the soldiers inside the

vehicle. Kevlar® 29 is ideal because it is lightweight and non-flammable and it offers protection from high temperatures (fire bombs, Molotov cocktails etc...). Kevlar® 29 can also withstand the harsh environmental conditions, found in hot climates. |

|

|

|

| 3. Kevlar® 49

is used for specialist boat hulls and in the aerospace industry. It is

popular as a material for boats because it is lightweight and can

withstand a considerable amount of force (torque - twisting force),

tensile stress and impact. Hulls manufactured from traditional materials,

such as fibreglass, are limited in their resistance to forces and stress.

Also, a lightweight boat is faster on the water and uses less fuel to

complete distances. Eurofighter is relatively light compared to other similar fighter jets, due to the selection of Kevlar ® 49 as a material in its manufacture. This means that it can fly faster and further, before in-flight refuelling is needed. It is more agile than its rivals due to excellent force (torque - twisting force) and tensile stress resistance. The plane is more likely to survive being hit by small arms fire, compared to other fighter planes, as Kevlar ® 49 has excellent impact resistance. |

|

|

|

| FURTHER ADVANTAGES OF USING KEVLAR | |

| Kevlar® has a range of

advantages, not only its relative low weight and high strength: Laminated Kevlar® is very stable at high temperatures and it is impact and scratch resistant. Kevlar® is often combined with other materials, to produce textiles with enhanced properties, such as fire resistant clothing for the Fire Services. Kevlar is used in some quality walking boots because it is waterproof (when combined with other materials as a composite) but also breathable, ensuring comfort. When Kevlar is used as a composite with rubber, it retains its flexibility. This composite material is used in the manufacture of Formula One Racing Car petrol tanks. The tank holds the petrol safely, even in the event of an accident. The material cannot be pieced by other car components, even during a high speed impact. The petrol does not escape / leak, avoiding fire and explosions. The lightweight tank, adds to the reduced weight of the entire vehicle, leading to a faster racing car. |

|

| DISADVANTAGES OF KEVLAR | |

| Kevlar® textiles tend to

absorb moisture. It must be combined with moisture resistant materials, if

there is a need for moisture resistance as a physical property.

Consequently, very few general cloths are manufactured with Kevlar®. Kevlar® reacts well under a tensile force (stretching force) but badly under a compressive force. It is not used where compression resistance is needed, such as bridge building or the structure of a building. It is difficult to cut and shape, unless through the use of special tools and equipment. Laminated Kevlar® is also difficult to machine and consequently special cutters are required. Special cutting techniques were developed to enable the manufacture of Kevlar® parts, for the Eurofighter. Kevlar® reacts badly to UV light (sunlight) unless it is protected / hidden from direct sunlight. Kevlar® suffers some corrosion if exposed to chlorine. |

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | |