| CLICK HERE FOR INDEX PAGE |

| LDPE (LOW DENSITY POLYETHYLENE) |

| V. Ryan © 2012 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

|

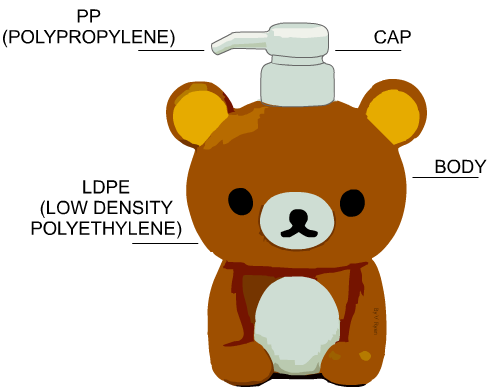

Carefully study the image of a hand wash bottle / soap dispenser. It is manufactured from LDPE (Low Density Polyethylene). It has been manufactured through the process called extrusion blow moulding. |

|

| Write three reasons for the use of LDPE for this type of product. |

| REASON 1: |

| REASON 2: |

| REASON 3: |

| SAMPLE ANSWERS |

| REASON 1: |

| LDPE is ideal for the extrusion blow

moulding process as it is a thermoplastic. It can be re-heated and

therefore shaped in various ways. These plastics can be re-heated and

therefore shaped in various ways. They become mouldable after reheating as

they do not undergo significant chemical change. Reheating and shaping can

be repeated. The bond between the molecules is weak and become weaker when

reheated, allowing reshaping. Thermosetting plastics cannot be used for this process. |

| REASON 2: |

| LDPE can be recycled, making it ideal for products with a short life cycle. Products of this type are usually clearly marked with a recycling symbol. Most supermarket customers routinely return empty ‘plastic’ bottles to the recycling bank, ensuring the materials like LDPE are reused. Many potential customers look to purchase products that help protect the environment or reduce damage to it. LDPE products fit this customer orientated criteria. |

| REASON 3: |

| LDPE is durable and will last along time. Often products such as soap dispensers are refilled. Consequently, LDPE has been chosen to withstand constant handling and reuse, long in excess of one fill with liquid soap. |

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE |