| CLICK HERE FOR INDEX PAGE | |||

| Mortise and Tenon Joints - Including the Wedged Mortise and Tenon | |||

| V. Ryan © 2002 - 2022 | |||

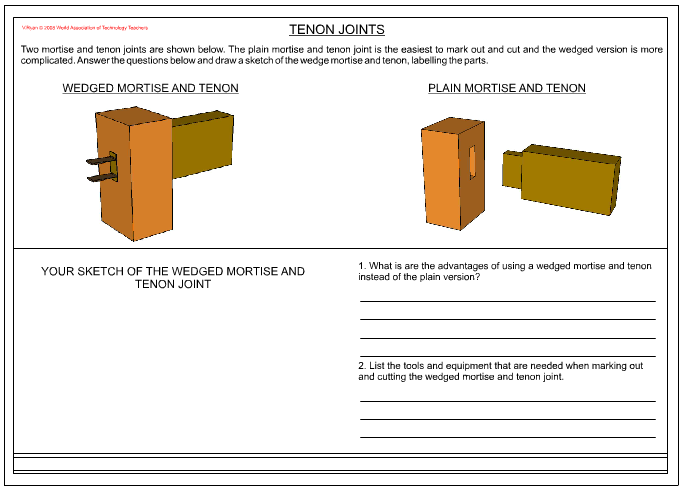

| PDF FILE - BASIC MORTISE AND TENON JOINTS - BOX LEARNING EXERCISE | |||

|

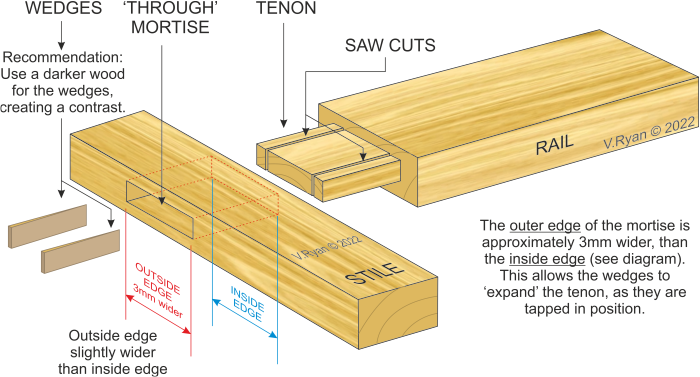

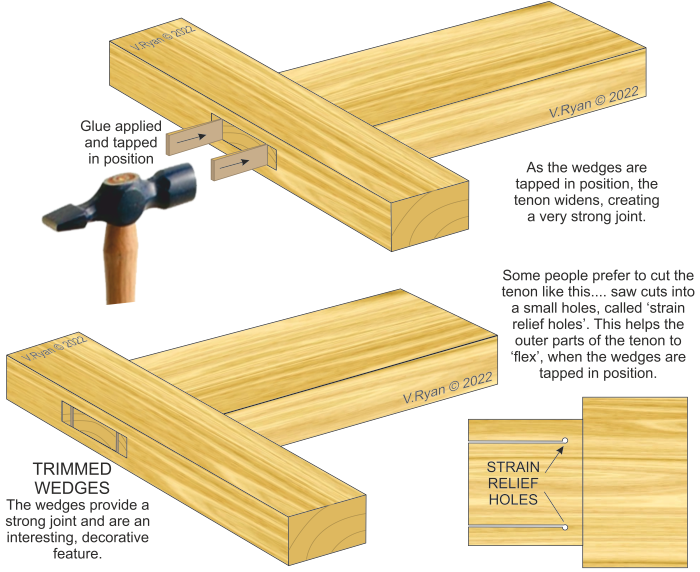

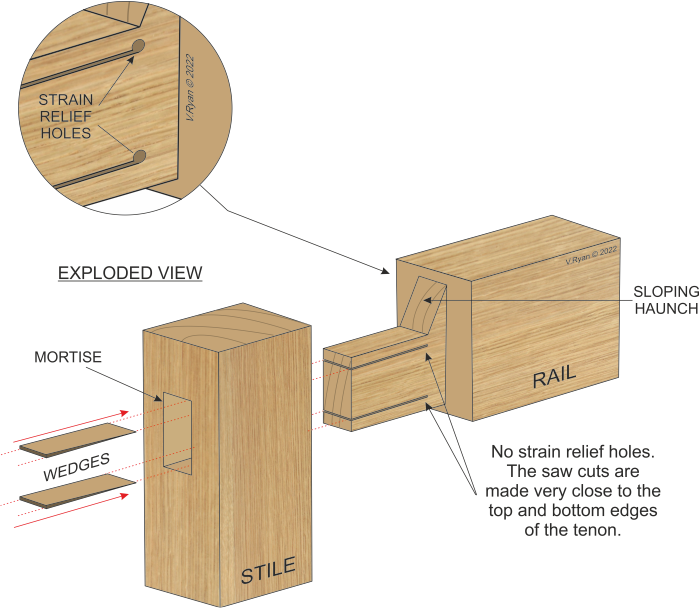

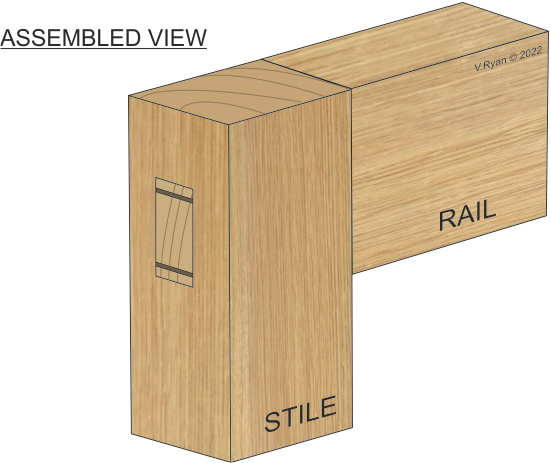

Below are two examples of ‘MORTISE AND TENON JOINTS’. These are used when making tables or cabinets and they are very strong when glued together with either PVA or cascamite adhesives. There are many different types of mortise and tenon joints. The Plain Mortise and Tenon joint (shown below) is very common and is widely used for the joints of tables. Although it is quite strong, if enough force is placed on the joint it will eventually break or come lose. On the other hand, the Wedged Mortise and Tenon joint is extremely strong because the tenon passes all the way through the mortise and is wedged at the other side. However, the Wedged Mortise and Tenon is more difficult to mark out and cut and requires much more technical skill. If the mortise and tenon joint is to used as part of a frame a secret or sloping haunch is used. The tenon does not show on the outer side of the joint and it gives greater gluing area, adding to the overall strength of the joint. The sloping haunch of the tenon can be clearly seen on the wedged mortise and tenon joint shown below. |

|||

|

PLAIN MORTISE AND TENON |

|||

|

|

|||

|

WEDGED MORTISE AND TENON |

|||

|

|

|||

|

|||

|

|||

| Some craftspeople prefer to drill ‘strain relief holes’ into the tenon (see the diagram below), before sawing the gaps / slots for the two wedges. Strain relief holes allow the outer part of the tenon to open more easily, when the wedges are tapped in position, ‘locking’ the joint together. An alternative view, is that there is no need for the strain relief holes, because the outer parts of the tenon will flex, if the saw cuts are made close to the top and bottom edges of the tenon. |

|||

|

|||

|

|||

| ROUND, WEDGED, MORTISE AND TENON | |||

|

|||

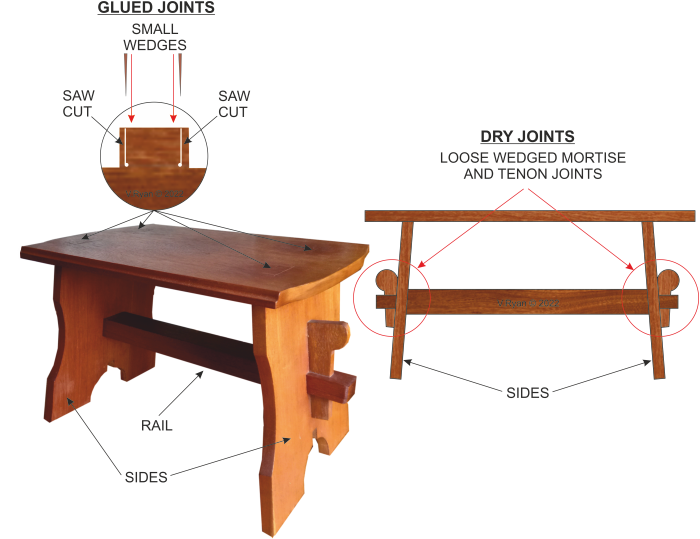

| LOOSE WEDGED MORTISE AND TENON JOINT | |||

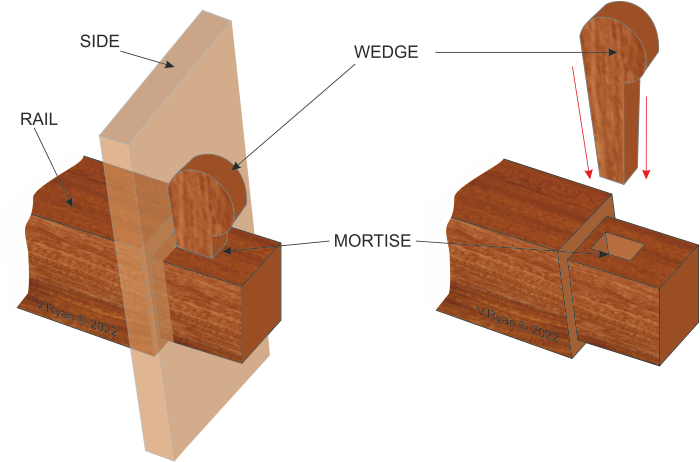

| A ‘loose wedged mortise and tenon’, is a ‘dry’ joint (see below). This means that glue is not required. Tapping the large ‘wedge’ in place creates friction, holding the joint together. Two loose wedged mortise and tenon joints, secure the central rail of this stool / table. They provide strength to the sides of the stool. | |||

|

|||

| The wedge is tapered slightly, corresponding with the taper of the mortise. When the stool / table is assembled, the each wedge is tapped in place, with a mallet. | |||

|

|||

|

PDF FILE - CLICK HERE FOR PRINTABLE VERSION OF EXERCISE SHOWN BELOW |

|||

|

|

|||

|

|

|

||

|

|

|||

|

QUESTIONS: 1. Draw an exploded view of one of the mortise and tenon joints shown above. 2. Explain why the wedged joint is much stronger than the plain joint. |

|||

|

|

|||