| CLICK HERE FOR INDEX PAGE | ||

| FITTINGS FOR METAL TUBE FRAMES - 1 | ||

| V. Ryan © 2004 - 2018 | ||

|

Joining lengths of steel / aluminium tube can be

achieved by using a variety of fittings. Normally steel tube frames are

bolted, brazed or welded together. Bolted frames can be dismantled and

reassembled as and when they are needed. Welded and brazed frames are

permanent. |

||

|

|

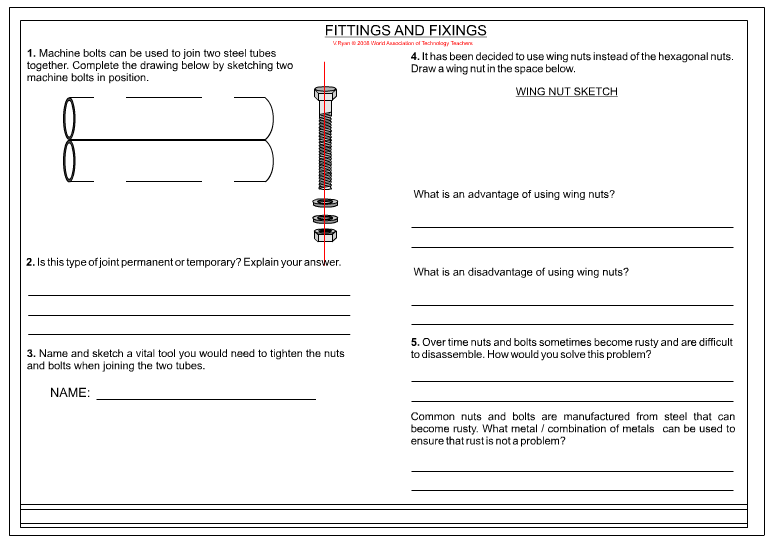

Machine bolts can be used to join tube. Holes are drilled first and the bolts, are pushed through. Using washers is important as they protect the surface of the tube and give a neater finish to the joint. Some bolts have a square neck that fits into the hole in the tube, giving a firm fit. (See diagram below). |

|

|

|

||

|

|

To ensure that the bolt settles into the drilled holes, a small depression is made at both sides of the tube. This gives a slightly flatter surface for the face of the bolt head and nut to rest in. |

|

|

|

||

|

Two spanners are needed to tighten a nut and bolt. The first spanner fits round the hexagonal head of the bolt and a second spanner is used to tighten the hexagonal nut. |

|

|

|

|

|

If the frame (for instance a trolley frame) is for

carrying light weights, then wing nuts can be used to join it together.

The advantage of using these is that they are tightened by hand.

However, this type of fitting is only hand tight and will not carry as

much weight as nuts and bolts tightened with a pair of spanners. |

|

PDF FILE - CLICK HERE FOR PRINTABLE VERSION OF EXERCISE SEEN BELOW |

||

|

||

|

|

||