| CLICK HERE FOR INDEX PAGE | |

| LIFE CYCLE OF NATURAL WOOD | |

| V. Ryan © 2012-2018 | |

| PDF FILE - CLICK HERE FOR PRINTABLE TEMPLATE - LIFE CYCLE OF A PRODUCT | |

VIDEO - Life Cycle of a Product  |

|

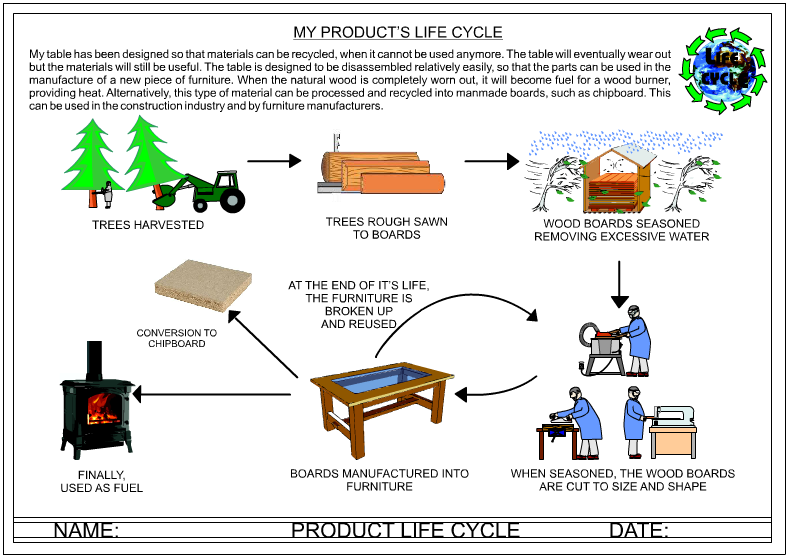

| STAGE ONE: The tree is harvested from a sustainable forest. Mechanisation has led to the development of equipment capable of cutting down hundreds of trees in a day. | |

|

|

| STAGE TWO: The ‘logs’ are transported to a sawmill and are ‘broken down’ (sawn) into boards. Every effort is made to reduce waste. Saw dust produced during this process is used in the manufacture of chipboard and MDF. | |

|

|

| STAGE THREE: The rough sawn boards are seasoned, a process whereby a large proportion of the water content is removed. If the process called ‘air seasoning’ is used, it can take months before the boards are ready for the next stage. Alternatively, the boards can be ‘kiln dried’. This requires energy and heat and is more expensive, although it takes a couple of days. | |

|

|

| STAGE FOUR: MANUFACTURE - The seasoned boards, are used by manufacturers and furniture makers, to construct products. Products range from windows and furniture to electric guitars and boats. | |

|

|

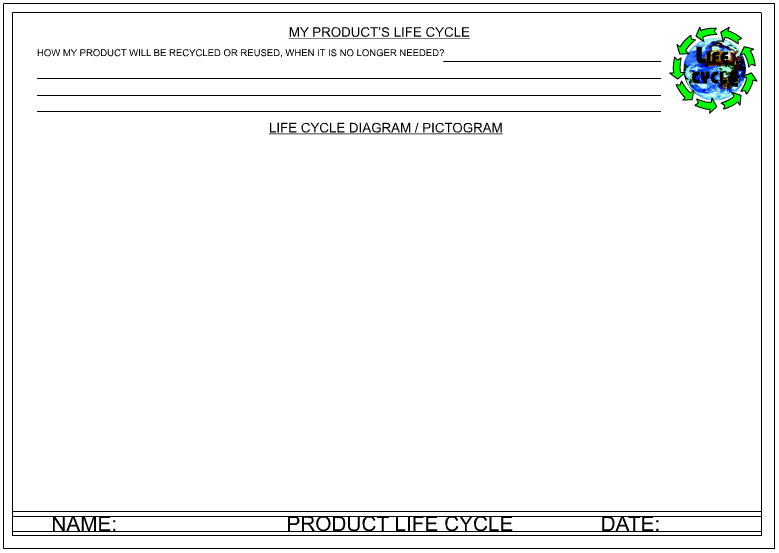

| LIFE CYCLE DESIGN DEVELOPMENT SHEET | |

|

|

| LIFE CYCLE DESIGN TEMPLATE | |

|

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | |

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE | |

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE | |