| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

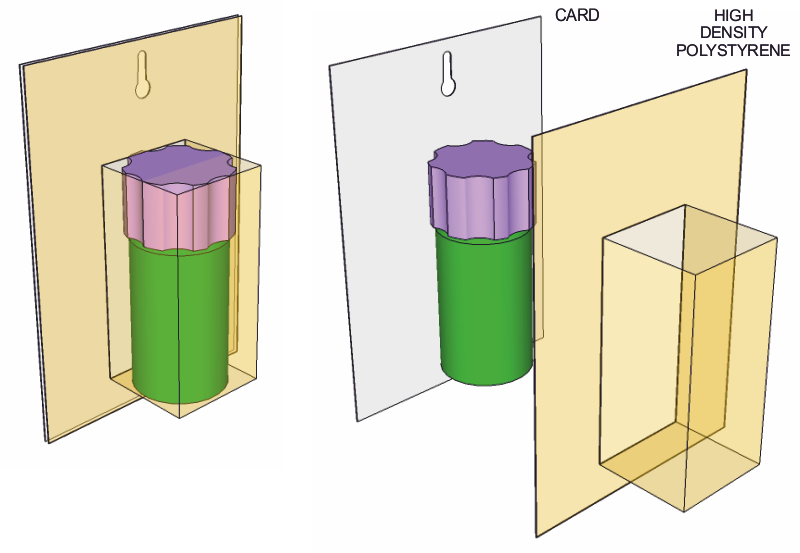

| The aerosol deodorant seen below has simple packaging. The deodorant container only needs simple protective packaging. This packaging is manufactured from card and vacuum formed high density polystyrene (HDPE). The polystyrene is transparent and tough. All the packaging can be recycled. | |

|

What are the advantages of having packaging of this type? 1. The cost of manufacturing the package is cheap compared to a complicated box. 2. Less material is used - this is good for the environment. 3. The package is easy to open and reseal. 4. Limited information can be printed on the packaging. This is a good point, as an aerosol can only requires simple instructions. 5. The package is light-weight. 6. The deodorant can be seen through its transparent cover. |

|

| The plastic forming films such as polyvinyl chloride (PVC), polypropylene (PP) and polyester (PET) are formed through the use of heat, and are usually colorless and transparent. High density polystyrene is also suitable for blister packaging | |

|

|

| What do you think are the advantages and disadvantages of this type of packaging? Is it suitable for a perfumed product? | |

| CLICK HERE TO SEE HOW BLISTER PACKAGING IS MANUFACTURED | |

| CLICK HERE FOR PRODUCT DESIGN INDEX PAGE | |