| CLICK HERE FOR INDEX PAGE | |

| JIGSAWS | |

| V. Ryan © 2006 - 2023 | |

|

Jigsaws are general cutting and shaping tools. They

are provided with a selection of blades suitable for cutting and shaping

a range of materials. They are ideal for cutting thin manmade boards

such as plywood and MDF and they are capable of cutting detailed curves.

They can also be used to cut kitchen tops and quite thick material. Thin

material (4mm to 6mm) can be cut quite quickly but great care must be

taken when cutting thicker material (6mm upwards). |

|

|

|

|

1. Always plug

power tools into a RCB (circuit breaker) as a safety measure against

electrical faults. |

|

|

Below is a typical jigsaw. The ON/OFF switch is

located on the handle as well as the switch lock. When the switch is

pressed the jigsaw starts although holding the switch in position whilst

cutting can be uncomfortable. However, if the switch lock is also

pressed this holds the switch in position which means that finger

pressure on the switch can be released and the jigsaw continues to work. |

|

|

|

|

|

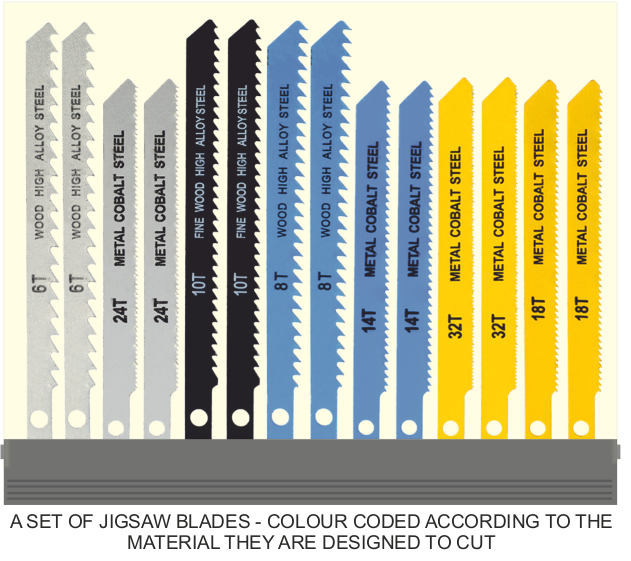

A selection of blades can be fitted to a jigsaw. The

type of blade depends on the material. Furthermore, coarse blades with

‘rugged’ teeth are normally used to make rough cuts whilst blades with

fine, numerous teeth are used to cut and shape very accurately. |

| TYPICAL SET OF JIGSAW BLADES | |

|

|