|

The sheet brass is marked out using an engineers try square and scriber. The arc is scribed using spring dividers, after the centre of the arc has been marked with a centre punch. |

||

|

||

|

The location of the drill holes are marked out using a centre punch. This means that the drill bit will not slip when the brass is drilled. |

|

|

|

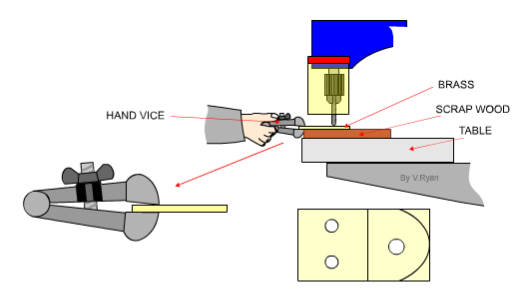

The hand vice is one safe way of holding the brass

whilst drilling. It has two jaws that are closed by turning a wing nut. |

||

|

||

|

Tinsnips are used to cut away the waste brass. The waste is stored in recycling bins until there is enough to sell for scrap metal. |

|

|

| A hand file is used to smooth all the sharp edges. This can be followed by using emery cloth. This will smooth the brass further. |

|

|

|

Folding bars are used to fold (bend) the brass to exactly 90 degrees. Force is exerted on the brass whilst it is held in the folding bars. Care must be taken not to slip when carrying out this procedure. The edges of the brass will still be relatively sharp. |

||

|

||

| The slide is manufactured using the same

metalworking techniques. The table is ready for assembly and dispatch to the shops or directly to the customer. |

||

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | ||