|

|

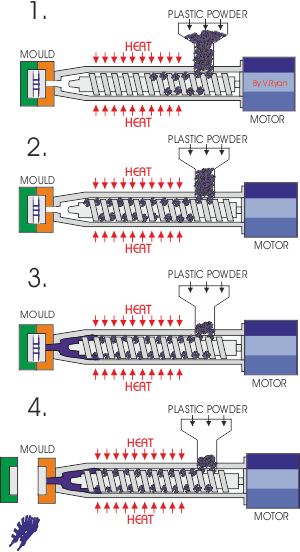

Materials such as polystyrene, nylon, polypropylene and

polythene can be used in a process called injection moulding. These are

thermoplastics - this means when they are heated and then pressured in a

mould they can be formed into different shapes. |

|

|

|

|

1. Granules of plastic powder (note the plastics listed above) are poured or fed into a hopper which stores it until it is needed.

3. A motor turns a

thread which pushes the granules along the heater section which melts then

into a liquid. The liquid is forced into a mould where it cools into

the shape (in this case a DVD storage unit).

4. The mould then opens and the unit is removed. |

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | |