V.Ryan © 2023

Water jet cutters are used widely in manufacturing, for the precise cutting and shaping of a range of highly resistant materials, as well as softer materials.

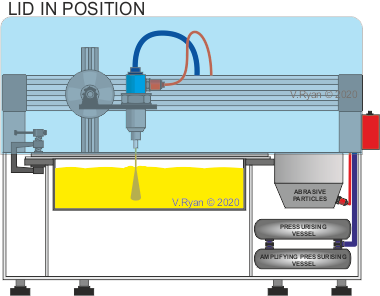

Water is first ‘pressurised’ by the means of a pressure vessel (also called an accumulator or intensifier pump). It is then focussed, to a narrow beam of high pressure water. When the water exits the nozzle, it is at a speed greater than the fastest jet fighter. The pressurised jet of water, can cut and shape soft materials such as rubber. If a fine abrasive material, such as sand, aluminium oxide or granite is added to the jet, highly resistant materials including steel and ceramics, can be cut and shaped, with precision.

This water jet cutter has a ‘transparent lid, for safe operation. If the lid is left open, the cutter cannot be operated. This type water jet cutter is suitable for schools and colleges.

A computer / laptop, is used to draw the design, using software such as CorelDRAW or AutoCAD. The finished design is converted to a dxf file and exported to the water jet cutter. This file drives the cutter’s movement and speed, transferring the design to the material being cut.