V.Ryan © 2023

The nozzle of the dynamic head, is a complex piece of engineering. It typically needs changing every 500 hours, although this varies, depending on the pressure of the water / particle mix, the material being cut and the speed of movement. The main parts of the nozzle are manufactured from tungsten carbide.

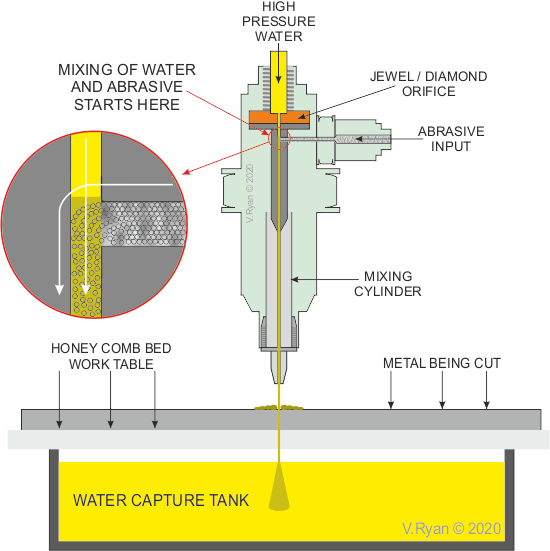

Water under very high pressure enters the top and is focussed by the ‘jewel / diamond orifice’. This material can withstand the immense pressure of the water, resisting wear and tear.

The abrasive enters from the side of the nozzle, through the ‘input’, mixing with the high pressure water. As the ‘water / abrasive mixture’ travels through the ‘mixing cylinder’, the mix of water and abrasive particles becomes uniform. This ensures a uniform cut (uniform width and surface finish), when it finally exists the nozzle and cuts through the material on the bed / working table.

This type of cutter can cut and shape a large range of materials accurately, including: steel (including metal foams), copper, aluminium and other non-ferrous metals, textiles, leather, paper, composites (including carbon fibre composite), ceramics (such as tiles) and many more.

The water and abrasive ‘grit’ are captured and recycled for further use.

The material being cut, does not distort due to the effects of heat, as it would on other types of cutter.

Adjusting the height of the nozzle, from the surface of the material, determines the width of cut. This means that different cut widths can normally be achieved, without the need to change the nozzle.

Multi-axil water jet cutters (5 Axil water jet cutter) can cut complex 3D shapes.

Water Jet Cutters are computer controlled and driven by Computer Aided Design (often dxf files). A file can be altered and edited, when required.

This type of cutting does not produce dust. The cutting solution and capture tank, ‘capture’ the waste material.

The edge left by the cutting process is smooth.