The laser cutter / engraver uses a laser ‘beam’ to etch the shapes to precisely the correct depth. The laser machine takes a fraction of the time to manufacture a piece of work of this type compared to traditional methods.

Comparative size

| CLICK HERE FOR INDEX PAGE |

| LASER CUTTING / ETCHING MACHINES -1 |

| V. Ryan © 2007-2023 |

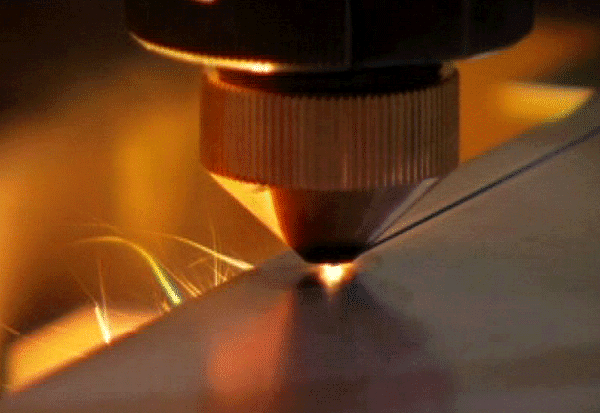

| Laser cutting and etching machines are relatively new in schools and colleges although the first industrial machine was introduced in 1988 by a USA based company called EPILOG. Laser cutters/etching machines are capable of very accurate work as a laser is used to etch or cut material precisely. They can be used in the cutting/ shaping of precise parts for prototype architectural models and etching a range of materials such as glass, marble, woods, plastic and even stainless steel. |

| A framed engraving of a family coat of arms is shown

below. Inside the wood frame is a small sheet of glass and the coat of

arms has been engraved/etched into the top surface using a laser

cutter / engraver. Before the introduction of laser cutters this process

would have taken a considerable amount of time and the coat of arms would

have been engraved by a skilled craftsperson, using a range of

sophisticated glass engraving tools. The laser cutter / engraver uses a laser ‘beam’ to etch the shapes to precisely the correct depth. The laser machine takes a fraction of the time to manufacture a piece of work of this type compared to traditional methods. |

|

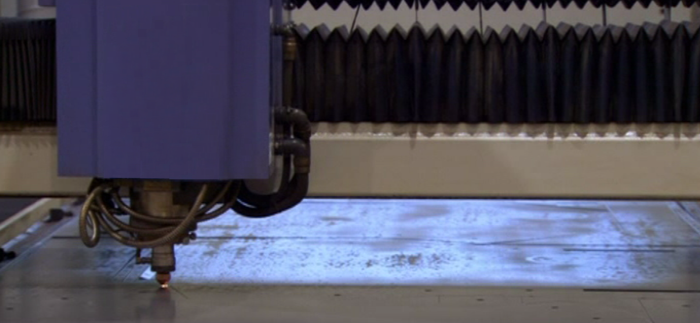

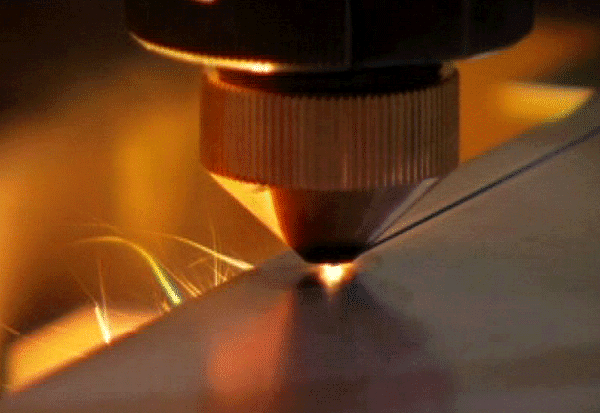

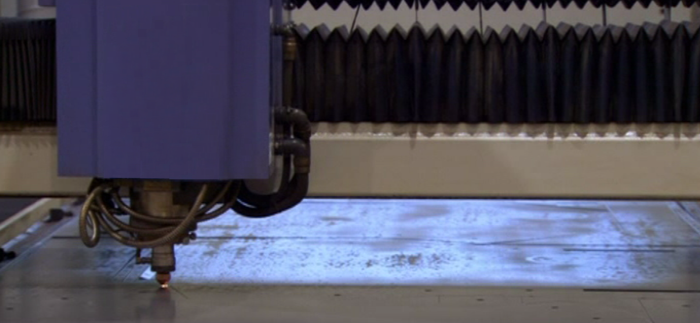

| LASER CUTTING STEEL PLATE |

|

|

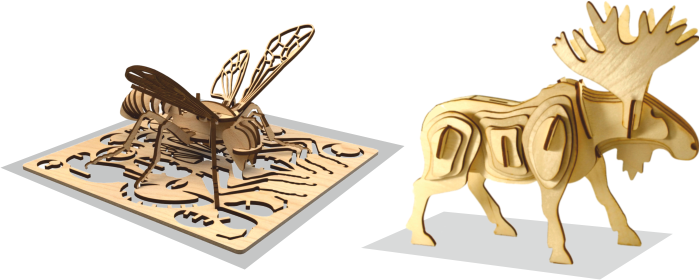

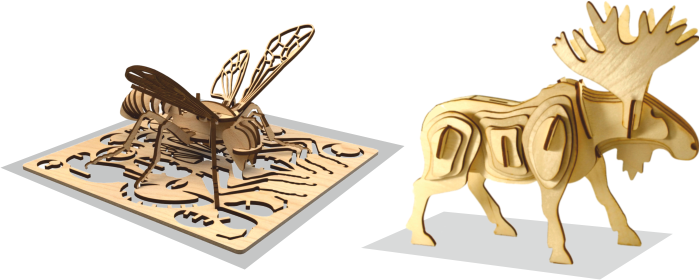

| More examples of objects engraved / cut using a laser cutter/etching machine are shown below. |

|

|

| A basic image of a typical Laser Cutter / Etching Machine is shown below. The example shown is no larger than a typical photocopier. A vacuum bed holds the work to cut/ engraved securely and the lens system directs the laser as it cuts / etches the material. |

|

| ALTERNATIVE DETAIL IMAGE OF AN ALTERNATIVE LASER ETCHING / CUTTING MACHINE |

|

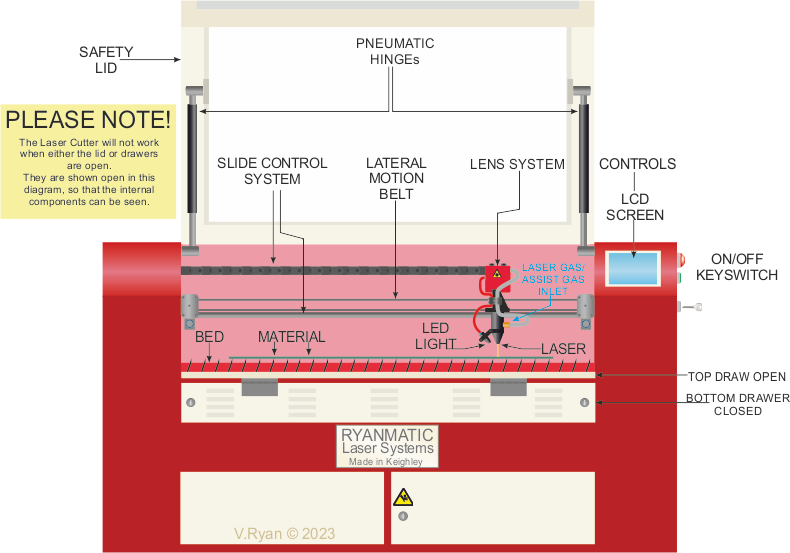

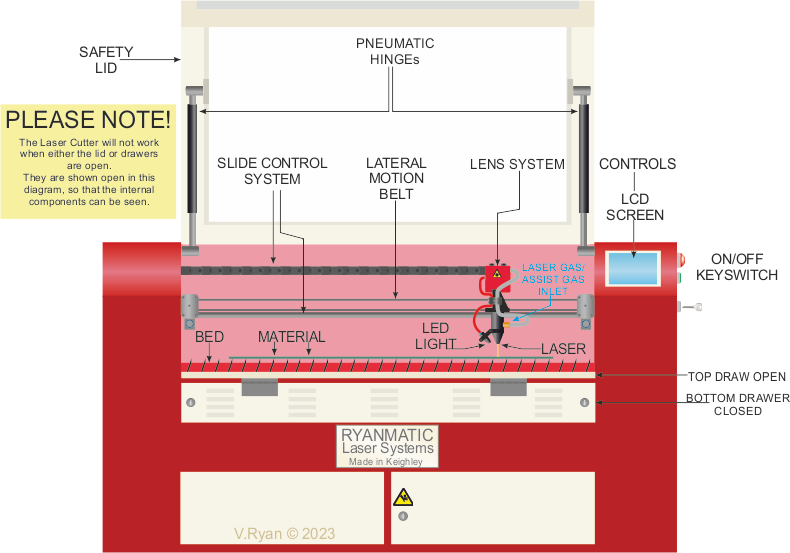

| DETAILED LABELLED DIAGRAM |

|

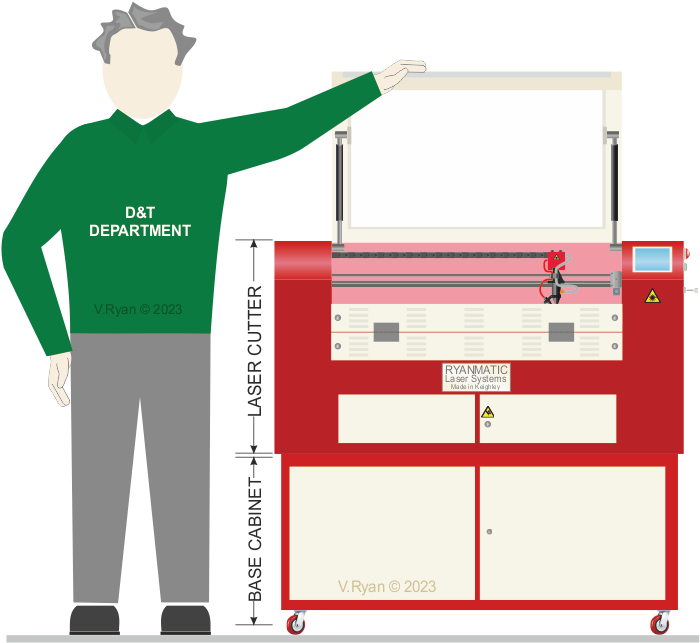

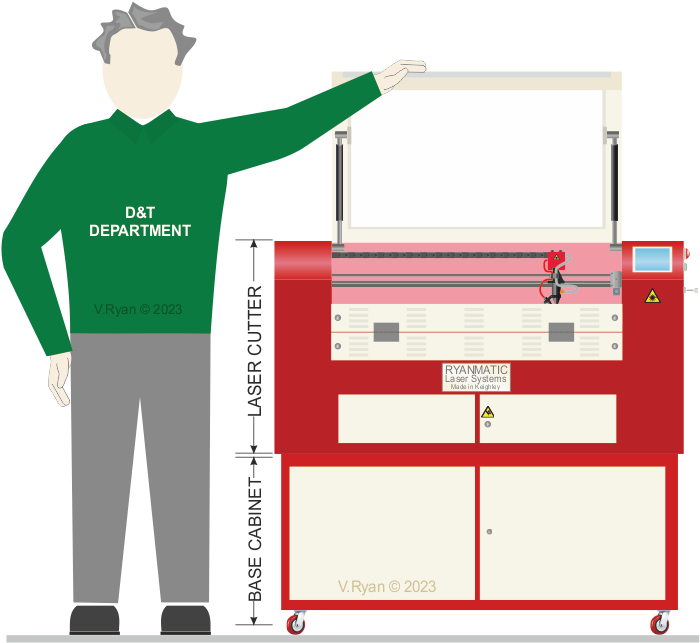

| LASER ENGRAVING AND CUTTING MACHINE Comparative size |

|

| CLICK HERE FOR CNC INDEX PAGE |

|

|