| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

|

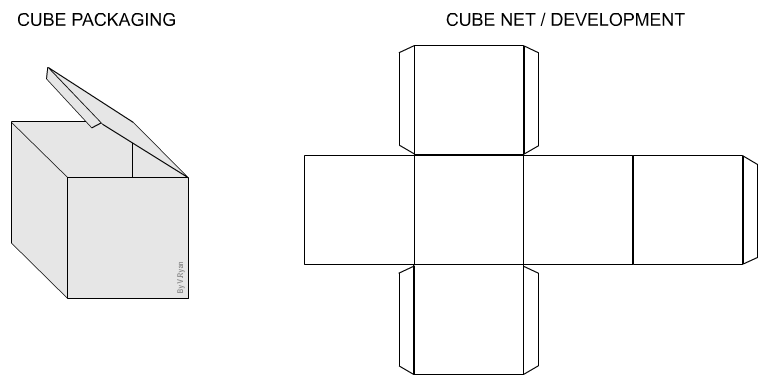

Look at a typical product on a supermarket shelf. It’s packaging started life as a flat development / net, probably printed on a piece of card. It was then cut out, folded and glued to form the package. A simple net / development for a cube like package is seen below. |

|

|

|

|

|

|

|

|

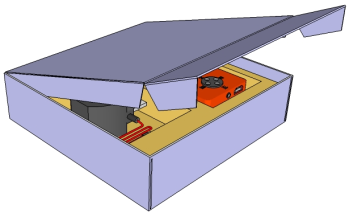

The packaging of a modern mobile phone is seen below. Mobile phones arrive in the shops in stylish boxes / packaging. Each package is manufactured from a material such as quality card. The insert is normally made from either lower quality, recycled card or vacuum formed hi-density polystyrene. This protects the phone and charger inside the package. |

|

| MOBILE PHONE NET / DEVELOPMENT FOLDED TO FORM THE PACKAGING | |

|

|

|

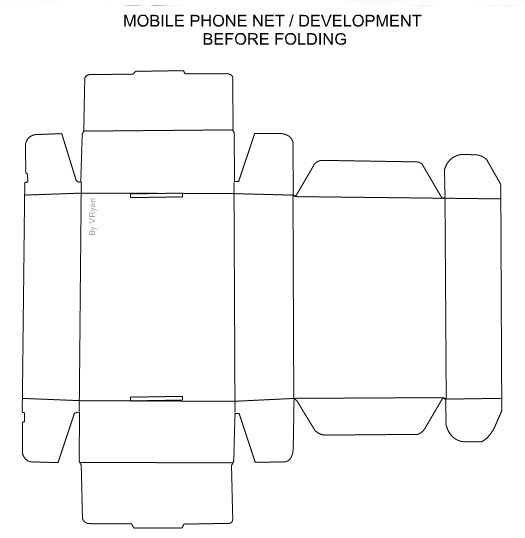

Card is popular packaging material because it is cheap and it can be

recycled. Also, colour and images can be applied using a number of

printing techniques. Normally the card is lacquered to give the box a

gloss / satin finish. Often the packages are cuboid in shape as this means that they can be transported and stacked on shelves easily, efficiently using space. Below is a ‘development’ / ‘net’ of the mobile phone packaging. |

|

|

|

|

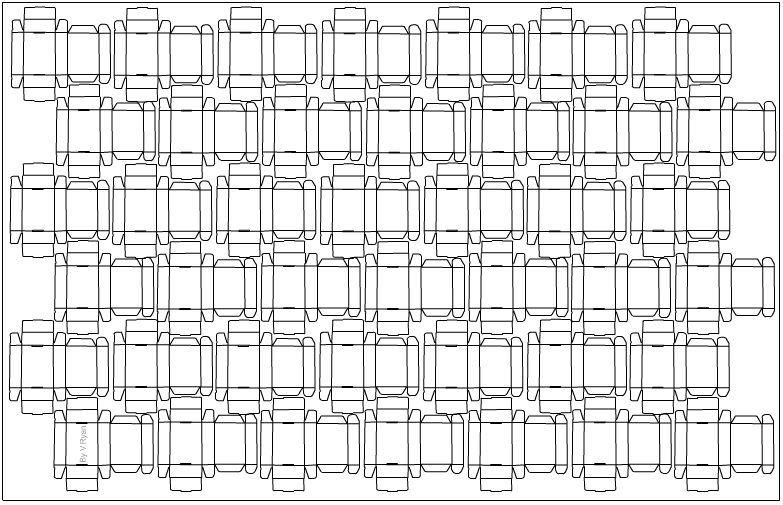

Packaging for almost any product is made in multiples. The only time a

single package / net is manufactured is usually when a prototype package

is required, so that it can be tested and improved. In industry a large, single sheet of card will be used to manufacture many individual developments / nets. The diagram below is a typical layout. It shows multiple nets of the mobile phone packaging, printed out on a single piece of card. This reduces waste and is a cost effective way of manufacturing packaging. |

|

|

|

|

The mobile phone packaging has been arranged as multiple nets, with very

little space between each one. This arrangement of shapes is called a

tessellation. A tessellation is a shape that is repeated over and over

again without creating gaps or spaces. A Tessellation is sometimes

called ‘tiling’. In industry it may be necessary to make thousands of the same type of package. In order that materials are not wasted, the developments / nets are organised on the card in such a way that there are only small gaps between each individual shape. Special cutters called Die Cutters, are pressed into the material to stamp out the nets / developments, which are then folded by machines to from the packages. (CLICK HERE FOR EXAMPLE OF DIE CUTTERS) |

|

|

|

|