| CLICK HERE FOR INDEX PAGE |

| |

| BLACKSMITH'S SETTS |

V.Ryan © 2020 |

| |

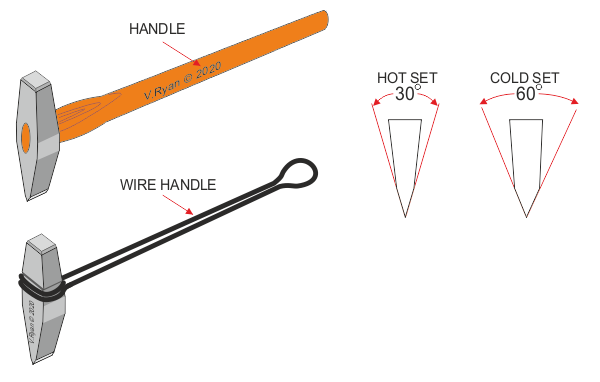

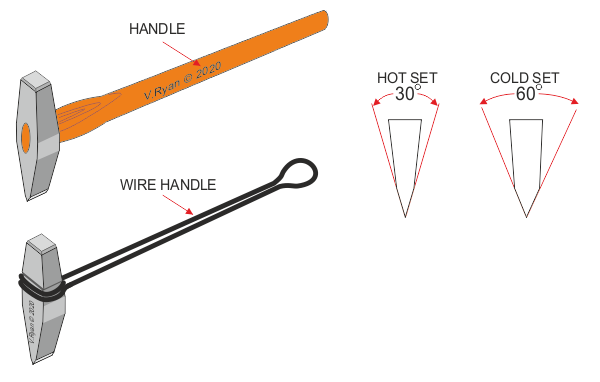

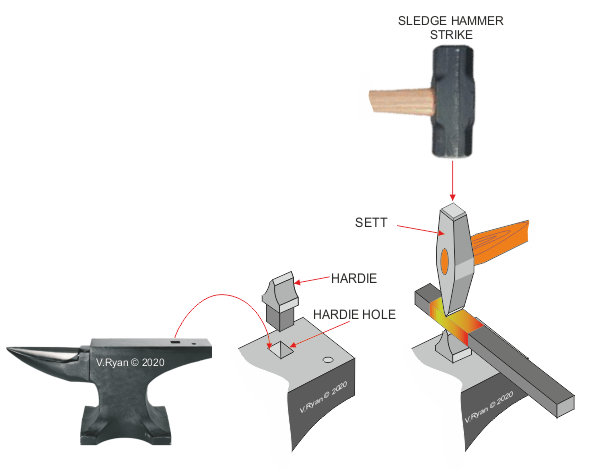

A sett is a ‘chisel’ used by Blacksmiths. A sett will have either a wooden or wire handle, formed from steel (see opposite). They are normally used in conjunction with a ‘hardie’, which sits in the hardie hole of the anvil.

Setts are in to forms, cold setts for cutting metal when it is cold and hot setts for use when cutting hot metal (as seen below).

The angle ground at the ‘cutting edge’ of a cold set is 60 degrees, whereas the hot sett has an angle of 30 degrees. |

| |

|

| |

|

|

| |

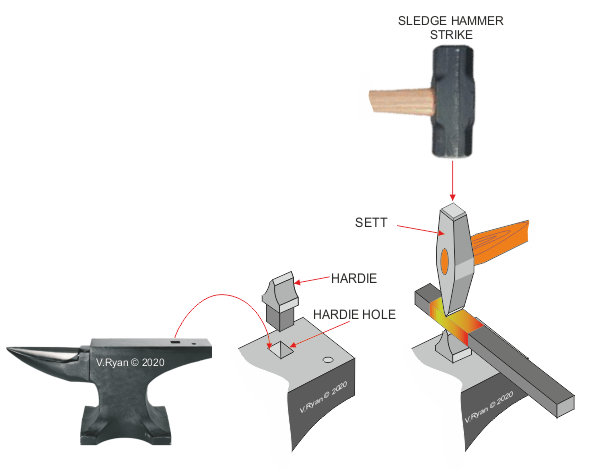

| The hardie sits in the hardie hole of the anvil. The metal to be heated to ‘yellow heat’ and placed between the hardie and the sett. The Blacksmith’s Assistant uses a sledge to strike the sett, creating a ‘nick’ in the top and bottom surfaces of the metal. The metal is then turned round, so that a ‘nick’ can be produced on the other two surfaces. This procedure continues until the steel can be broken apart. The metal should not be ‘cut’ all the way through, it should be rotated, as described above. |

| |

|

| |

|

|

| |

|

| |

|

|

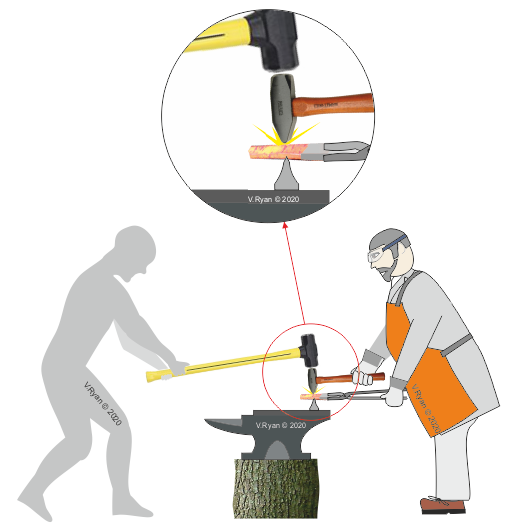

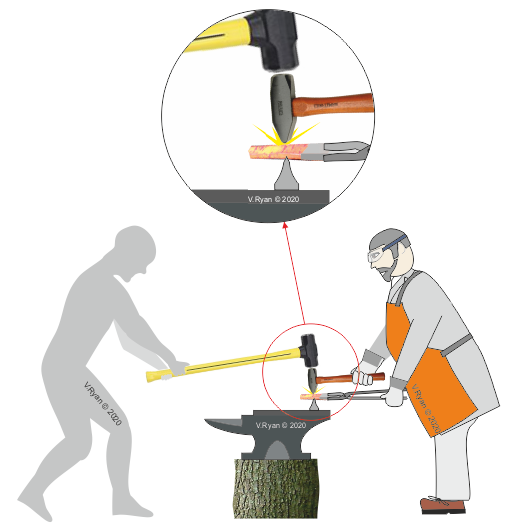

Lighter metals can be cut through a one person operation. The Blacksmith uses a Smith’s hammer to strike the metal, which sits on top of the hardie. The metal is rotated after each strike, creating ‘nicks’ on all the surfaces. This process is continued until the unwanted piece breaks off. Never try to cut all the way through, as this can lead to the hardie being damaged. The metal can be reheated between strikes, if required. |

| |

|

|

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|