V.Ryan © 2020

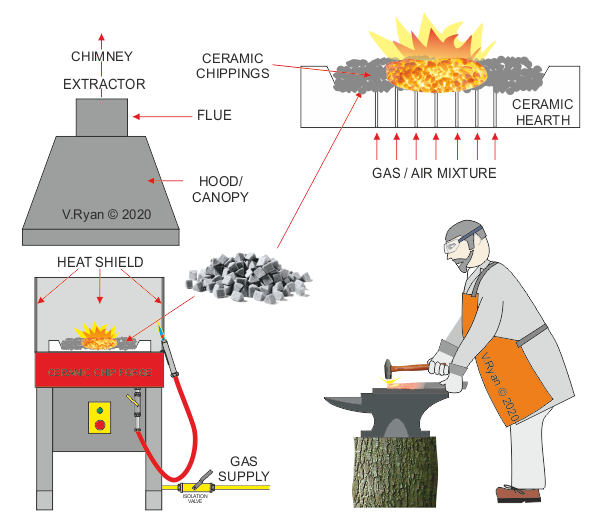

A modern, ceramic chip forge, is a good option for schools and colleges. Ceramic chips take the place of ‘coke’, but they should not be regarded as the fuel. The fuel is natural gas, which when ignited, burns at a high temperature, heating up the ceramic chips, which stores the heat. Heating of the metal to be forged, takes place in exactly the same way as with a traditional forge. It is placed in the heart of the fire, just below the surface of the heated ceramic chips. The ‘blast’ is normally a mixture of gas and air, applied through holes in the hearth. The blast can be adjusted in intensity.

Ceramic chip forges have the advantage of being connected to a gas supply, which provides much of the heat. This means that the forge can be ready for work, in less than fifteen minutes. They do not need a continuous supply of coke and require very little cleaning and preparation, compared to traditional ‘coke’ based forges. However, they tend to have a limited working area. The ceramic chips need replacing occasionally. THESE FORGES NEED A CONTINUOUS GAS SUPPLY (either piped or bottled (butane or propane)). They take little training to light and operate.

Coke based forges reach higher working temperatures, an advantage to a professional blacksmith. They do not need a supply of gas or even electricity. Manual bellows can be used to provide the ‘blast’ of air. A coke based forged, can be located in places without a gas or even electricity supply. This type of forge, takes longer to light and requires a level of skill and practice to keep at a working temperature.