| CLICK HERE FOR INDEX PAGE |

| |

| TONGS FOR FORGING |

V.Ryan © 2020 |

| |

|

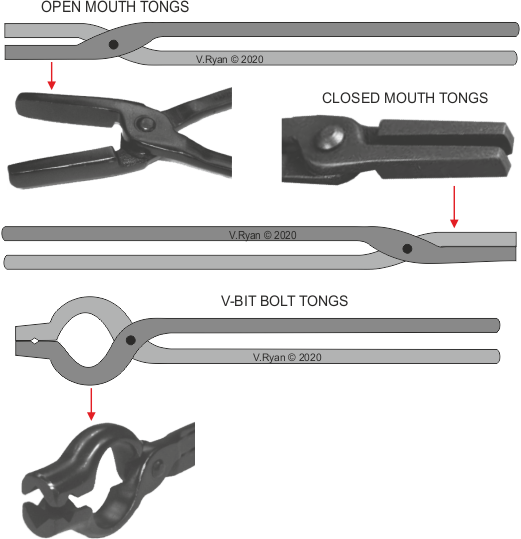

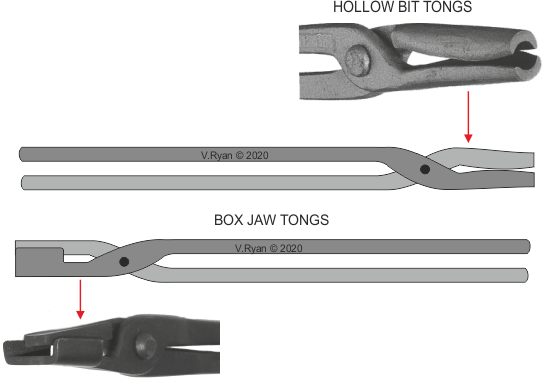

A range of tongs are available for forge work. They are used, when it is not practical or safe to hold the metal in the hand. Selecting the tongs to be used, depends on the nature of the work being carried out. They should hold the work comfortably and firmly. Tongs range in weight. For instance, lightweight tongs start at 900g and are ideal for school work and lighter forge work. Standard tongs range between 1300g to 1800g. Heavier tongs for substantial forge work, begin at 2kg.

The Blacksmith, selects the tongs required for a workpiece, through experience. He / she, knows which tongs fits the variety of shapes and forms being forged. A skilled Blacksmith will select the tongs to be used and then heat the jaws and hammering them carefully, until they fit the section of metal being held.

During forging, the tongs will become hot to hold, even with leather gloves being worn. It is necessary to quench tongs occasionally, to cool them down. |

| |

|

|

| |

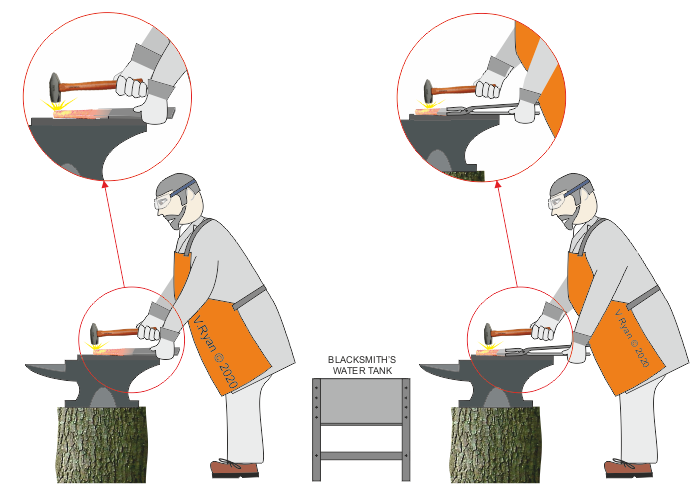

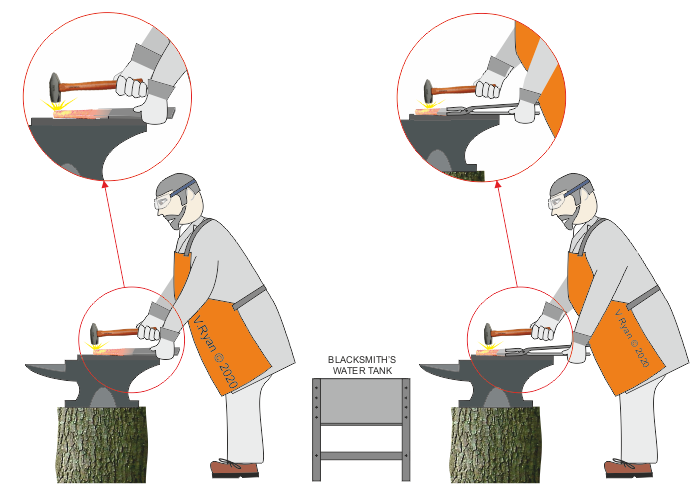

| The metal being forged is held by a gloved hand. This is safe because the glove protects the Blacksmith’s hand. When the heat conducts down the metal to the hand, the Blacksmith will use tongs. |

|

The short length of the metal being forged, means that it cannot be held directly in the hand. The Blacksmith selects the tongs ,according to the section / shape / form of the metal being held. Occasionally, the tongs will need cooling, to ensure that they do not heat up, making it uncomfortable to hold, or even impossible to hold. |

| |

|

| |

|

|

| |

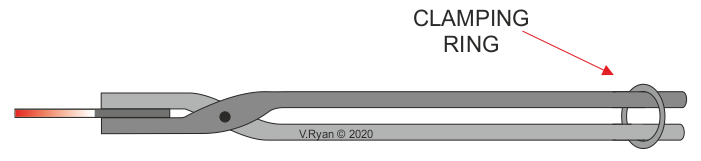

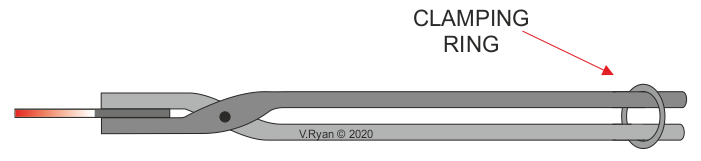

Using tongs for a long time can be difficult. Hands and fingers are put under strain and putting the tongs down to rest, interrupts the forging process.

A ring can be slipped other the handles of the tongs, which maintains the pressure needed to ‘clamp’ the metal being forged, between the jaws. This reduces strain on the hand. |

| |

|

| |

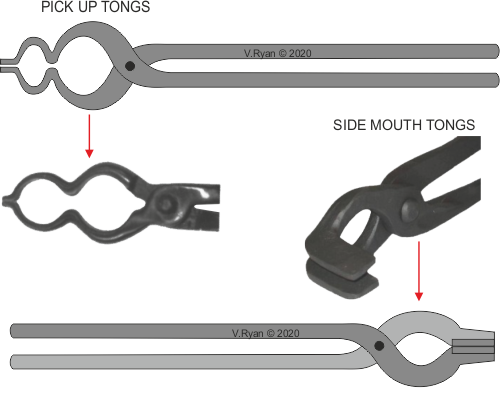

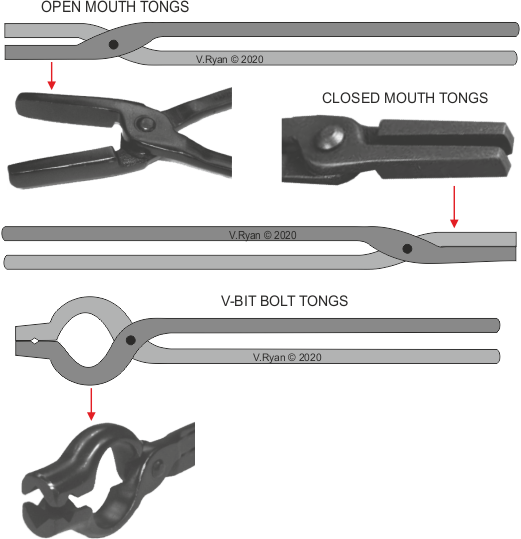

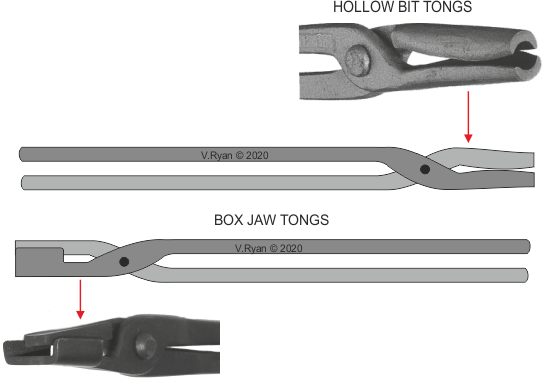

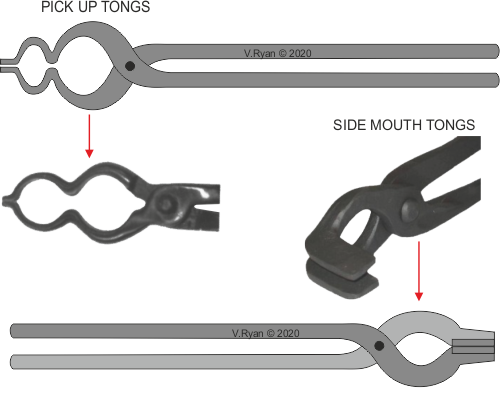

| A RANGE OF BLACKSMITH'S TONGS |

| |

|

| |

|

|

| |

|

| |

|

| |

| |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE |

| |

|

| |

|