V.Ryan © 2020

Wrought iron is ideal for forgework, although it is very difficult to acquire nowadays. It has a low carbon content, less than 0.08 percent. It is ideal for forgework, because it is ductile and malleable, due to its fibrous structure. However, wrought iron is not produced on a large commercial scale today.

As a replacement, medium carbon steels are used. They contain from 0.3 percent carbon to 0.7 percent. One such steel is called ‘black mild steel’.

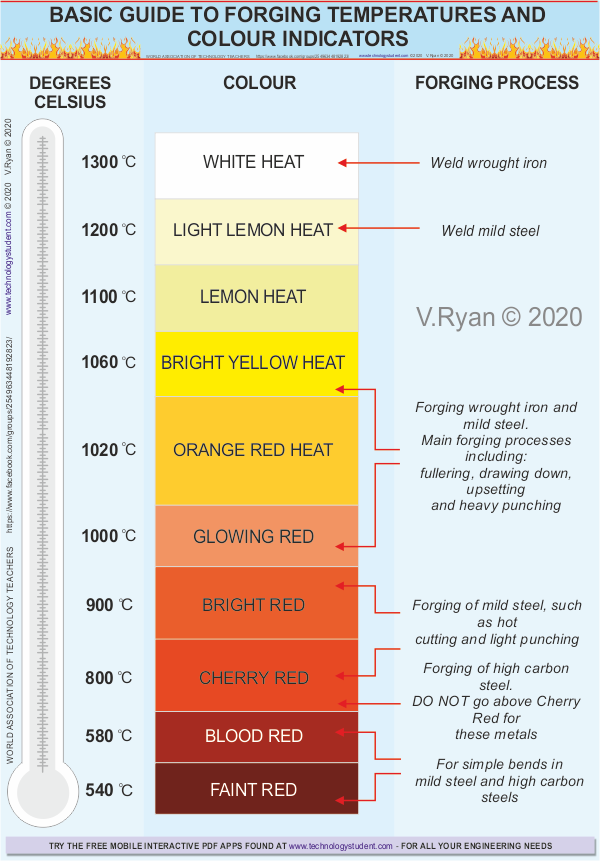

High carbon steels are sometimes used in forgework. However, care must be taken to ensure that these steels are not heated above cherry red heat (see colour indicator chart), as they will be damaged and their mechanical properties will be lost.

The Blacksmith uses a variety of sections including: round, hexagonal square and a range of flat strips.

Being able to read a heat indication chart is not easy, as ‘colour indicators’ will appear to be slightly different, according to the light present in the workshop, such as artificial light or even daylight. The forge should be situated in a workshop, where the light intensity does not vary.

FAINT RED to CHERRY RED - for general bends applied to mild steel and forgework on carbon steels.

BRIGHT RED - for punching and cutting metals such as mild steel.

GLOWING RED TO BRIGHT YELLOW - Forging wrought iron and mild steel including: fullering, drawing down, upsetting and heavy punching.

LIGHT LEMON HEAT - Welding mild steel.

WHITE HEAT - Welding wrought iron.