V.Ryan © 2020

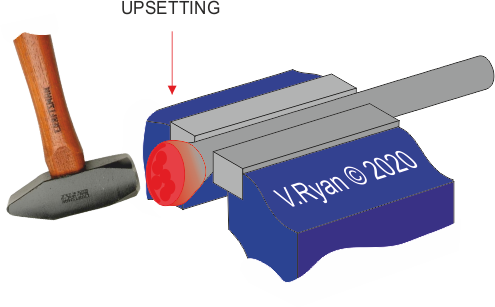

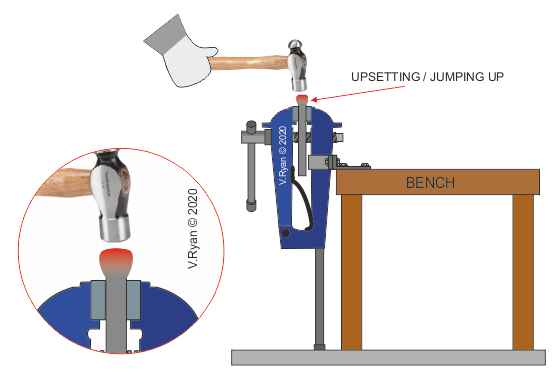

This process involves ‘thickening’ a section of the metal being forged. The metal Is heated to ‘yellow heat’ in the area to be thickened. A chalk line can be drawn on the metal, which marks the limit of the thickening. Chalk will show up relatively clearly, even after heating the metal. It may be necessary to cool the rest of the metal.

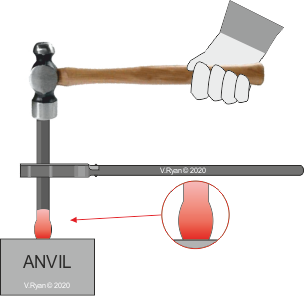

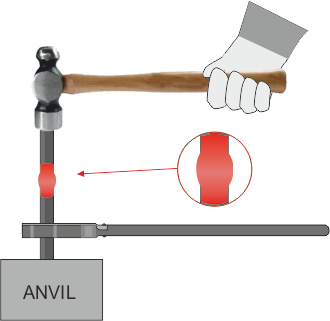

Pick up tongs are used to hold the metal, which is ‘bounced’ on the anvil. This should result in the heated area deforming, as seen in the diagram.

Another option is to strike the opposite end of the metal with a Blacksmith’s hammer, in this case a Blacksmith’s ball pein hammer is used