| CLICK HERE FOR INDEX PAGE | |

SPECIAL INKS - INKS THAT CHANGE AFTER CONTACT WITH WATER |

|

| V. Ryan © 2004-2021 | |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET | |

|

Another group of inks are those that change when they make contact with water. These are called hydrochromic inks. A possible application of this type of ink is a gardeners moisture tester. Some plants only grow properly if the soil they are in has the correct water content. |

|

|

A plastic moisture tester is pushed into the soil

alongside the plant. If the water content of the soil is at the right

level, the colour of the moisture tested should remain blue. However, if

the soil loses too much water then the colour changes to yellow. If too

much water is added to the soil then the colour changes to red. |

|

|

|

|

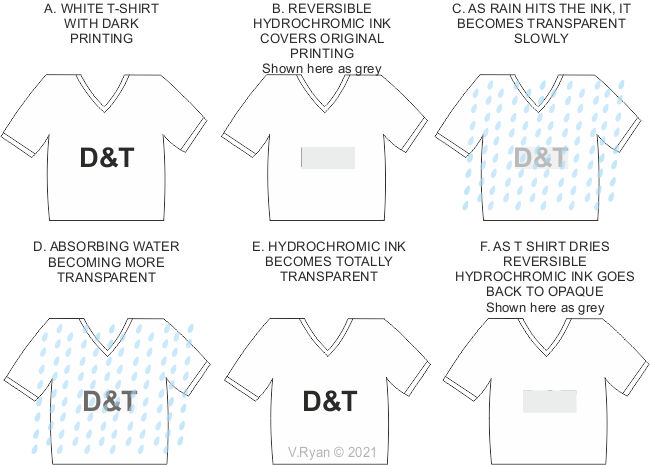

| REVERSIBLE WET AND REVEAL HYDROCHROMIC INKS | |

| These are dense (thick) inks that are applied to a surface, covering existing printing / an image. They are water based inks, applied usually through screen printing. The ink dries as opaque white. On contact with water, the ink becomes transparent, allowing the original printing / image underneath to be seen. When the ink dries it becomes opaque again, hiding the text / image. This type of ink can be applied to a range of materials including paper, plastics and textiles. It is not suitable for stretchable textile material. | |

|

|

| Another example of reversible hydrochromic inks is seen below. This is a non-slip bath mat. The reversible ink is opaque white when dry. When it is wet, it becomes transparent, revealing the true colour of the dog and some other details. | |

|

|

| Below is an umbrella that appears to change colour when it rains. | |

|

|

| IRREVERSIBLE HYDROCHROMIC INKS | |

| These are inks that change colour permanently on contact with water. They are available in a range of colours including magenta, green, brown, orange. They are applied to the surface material by screen printing or flexo printing, either using water based or solvent based inks. The type of surface the inks are printed on, determine the rate of colour change and is linked to the materials permeability. A surface with low permeability / absorbency, allows for a faster colour change. A material that absorbs the ink quickly, such as a textile material, slows down the colour change. | |

| One practical application is ‘nappies’. The irreversible hydrochromic ink printed on a nappy, becomes a solid colour, when wet (called colour changing wetness indicator). This is a useful early indicator of the need to change a baby’s nappy. | |

|

|

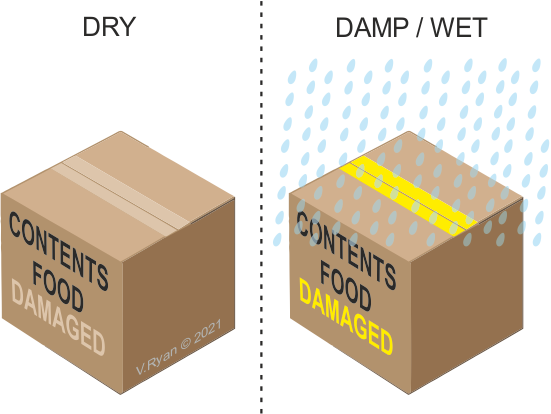

| Hydrochromic irreversible ink is used by the packaging industry. The images below, show a package with a special ‘indicator strip’, on the lid. If this package is stored in the wrong conditions (e.g. a damp warehouse), the indicator strip changes colour, showing that the contents have been tainted / damaged. The word ‘DAMAGED’ also changes to yellow. | |

|

|

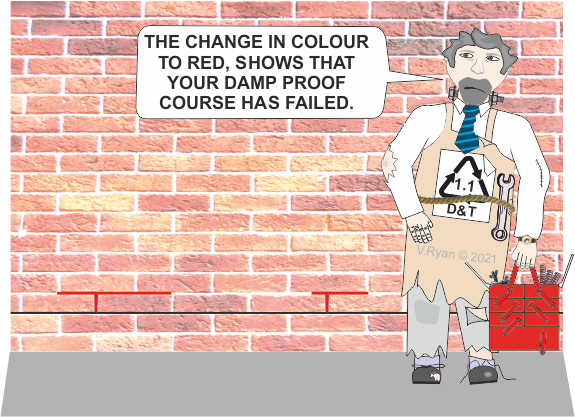

| Irreversible hydrochromic ink, is being tried as an indicator for damp in a building. A layer of cement mixed with the ink, is used above a damp proof course. The damp proof course keeps damp out of buildings. If the damp proof course fails, the cement layer above changes colour to red. This indicates that repairs may be needed. | |

|

|

|

|

|