| CLICK HERE FOR INDEX PAGE |

| MODEL MAKING - YOUR SELECTED DESIGN FOR FURTHER DEVELOPMENT |

| V. Ryan © 2017 |

Select one of your ideas, one your consider at this point to be your favourite. Make a model using simple materials such as card and styrofoam. Drawing pins, split pins and lollipop sticks may also be useful. |

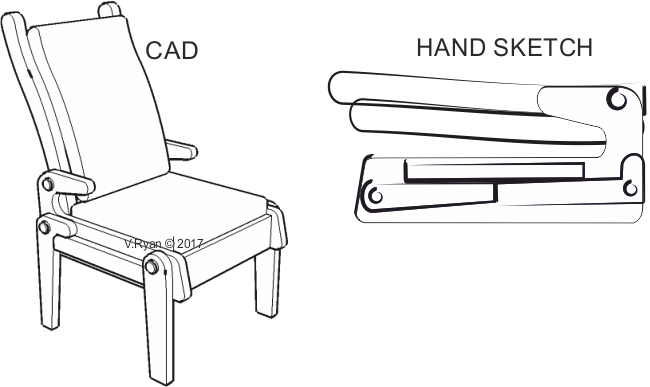

SKETCHES AND CAD The chair below folds into a cuboid shape, as seen in the CAd drawing. It can be placed in the back of a car for transport, as it is a regular shape. It has two comfortable cushions and the seating positioned has been determined to meet ergonomic demands. |

|

| MAKE A MODEL |

| The card and styrofoam model shown below, helped to determine the proportions of the chair and also the folding mechanism. Without a scaled model, testing the folding mechanism would have been difficult. |

|

| MANUFACTURE (NOT REQUIRED FOR EXAMINATION WORK |

Usually, a series of models are made as one way of developing the design. Below, is the final manufactured chair. A mixture of ash for the back rest, legs and arm rests. Plywood was used for the main seat frame. Two brass rotating joints for the back rest and four aluminium rotating joints for the legs (all manufactured on a centre lathe). IN MOST DESIGN AND TECHNOLOGY EXAMINATION WORK, MODEL MAKING IS THE FINAL STAGE |

|

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE |