| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

|

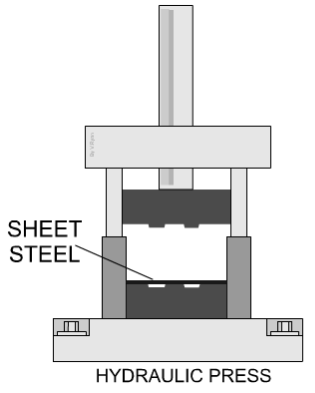

An hydraulic press is used to ‘press’ the pattern into the steel shelf and also to cut the two slots. Shaping sheet steel on an industrial press, through the force of compression is a common industrial process. The weight of the press, in addition to the hydraulic pressure, presses the shape and cuts the steel. |

| 1. The sheet steel is placed into the press. Normally, the operator closes a safety guard. If the guard is not in position, the press will not continue to work. This is a safety measure. |  |

|

2. The hydraulic press begins to move downwards, pressing the shape into

the sheet steel and cutting the two slots. 3. The upper mould moves upwards and the pressed sheet steel shape is removed. The edges are filed to remove shape burrs. |

| Look around your home and list items you think have been manufactured through the use of an hydraulic press. | |

| CLICK HERE FOR RESISTANT MATERIALS INDEX PAGE | |