V.Ryan © 2019

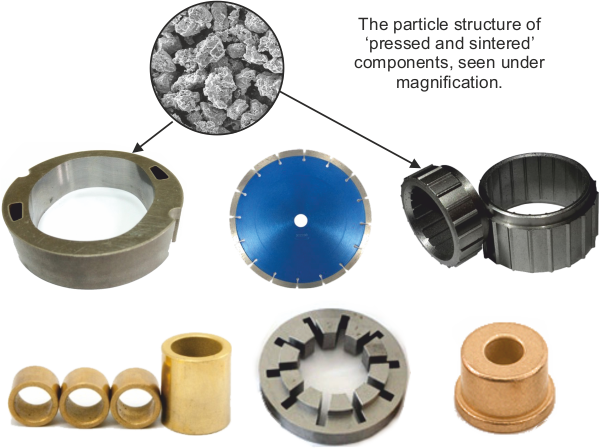

The powder is processed very carefully, to ensure that the particles are of a predetermined size. The particle shape may vary, depending on the component being manufactured. Preparing / processing the powder is complex, as the powder distribution will determine the density of the metal component. Some components may be manufactured, so that the density of the metal various, in different areas of the component, not possible with metals through other industrial processes. There may be a need for the manufactured component to be porous, allowing air or a liquid to flow through it, another advantage of this industrial process.

Powders can be dangerous if handled incorrectly. For example, they can be explosive or detrimental to health, if breathed in. Consequently, metal powders should always be handled according to the manufacturers instructions.

Capable of manufacturing relatively complex designs / components.

Suitable for mass production and long production runs.

Semi-skilled workers required during the production process.

A wide range of metal powders are available and can be used with this industrial process.

Speeds up the engineering process (manufacture) of many components - conventional engineering techniques would require more time during production and the work of skilled engineers.

Capable of producing a component with varying densities.

Mixtures of different metals / alloys can be used.

Several stages of manufacture, are involved in this industrial process.

Not economic, for prototype / one off production.

An expensive and precise mould is required.

The density of the final metal component, is likely to be lower than one manufactured through conventional engineering processes.

The finished component, may have a level of porosity, allowing liquids and gases to be absorbed.