| CLICK HERE FOR INDEX PAGE |

| |

| STEREOLITHOGRAPHY |

V.Ryan © 2019-2023 |

| |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| |

| CLICK HERE FOR POWERPOINT VERSION OF WORKSHEET |

| |

| PDF FILE - CLICK HERE FOR BOXED LEARNING EXERCISE |

|

| Stereolithography starts with a design produced through the use of CAD software. The 3D design is exported as a STL file (Standard Tessellation Language). It is this file, that is used to drive the SLA ( StereoLithographic Apparatus) machine, which manufactures the product / component. |

| |

|

|

| |

| This is an industrial process, involving liquid resin (a polymer) stored in a tank, which is solidified layer by layer, through the use of a laser. The product / component is ‘built’ on a platform, which moves down microns ( a micron = one thousandth of a millimetre) at a time. The laser solidifies a layer, before the platform moves down, allowing the laser to solidify the next layer. This process continues until the product / component is complete. The laser process, fuses the layers of resin together, resulting in a solid object. In summary, the stereolithographic process, converts liquid polymer to a solid component / product. |

| |

|

| |

| STEREOLITHOGRAPHY - SAMPLE PRODUCTS / COMPONENTS |

| |

|

| |

|

|

| |

| ADVANTAGES OF STEREOLITHOGRAPHY |

Ideal for the manufacture of prototypes.

Efficient use of materials - no waste.

Cost effective for one-offs and low production numbers.

Solid and flexible components / products can be manufactured through this process.

Produces a smooth surface finish.

Can produce clear / transparent or opaque components.

A number of resin based components can be manufactured in the same tank, at the same time.

This process can manufacture products that cannot be manufactured through traditional engineering methods. |

| |

| DISADVANTAGES OF STEREOLITHOGRAPHY |

Only resin / polymer components / products can be manufactured.

The structural strength of the product / component is limited, due to the nature of resin / polymers.

The initial set-up of machinery (SLA machine) is expensive.

Resin has limited resistance to UV light (including sunlight). |

| |

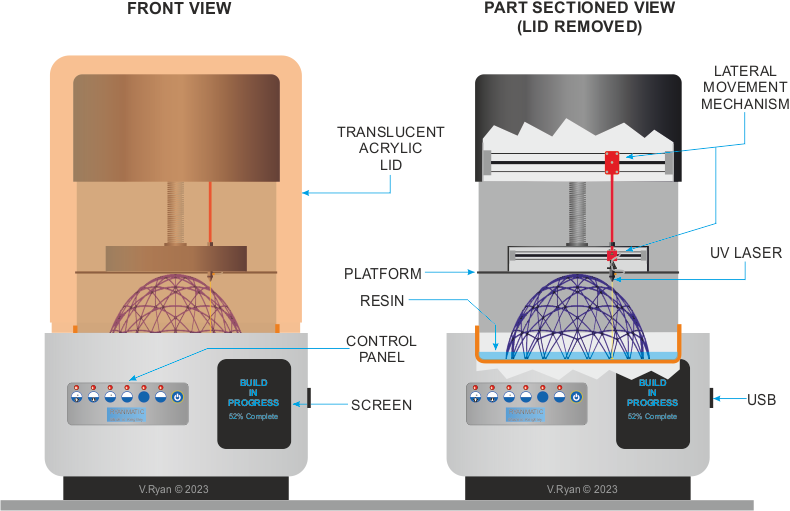

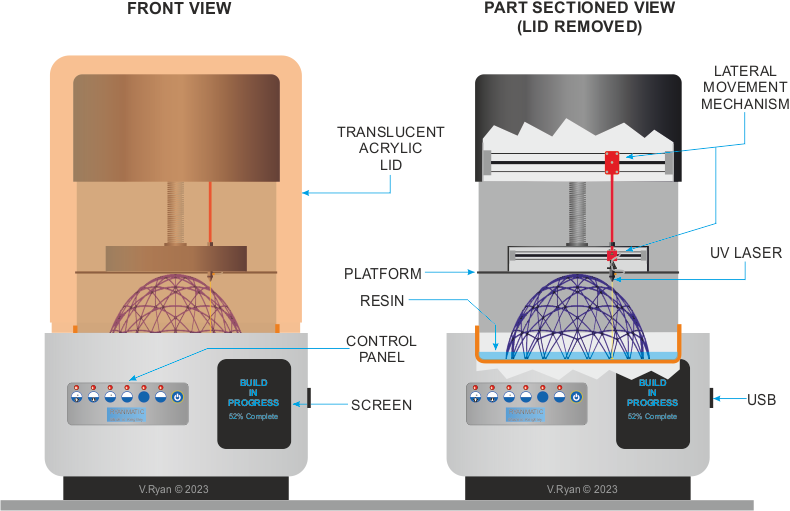

| DESKTOP UPSIDE DOWN / INVERTED STEREOLITHOGRAPHY |

| |

| This is a process whereby the build table / platform is lowered into resin. A UV laser ‘hardens’ each layer, building layers downwards. It is the most common form of desktop stereolithography. |

| |

|

| |

| ANIMATION OF THE BASIC 'DOWNWARDS / INVERTED PROCESS |

| |

|

| |

|

|

| |

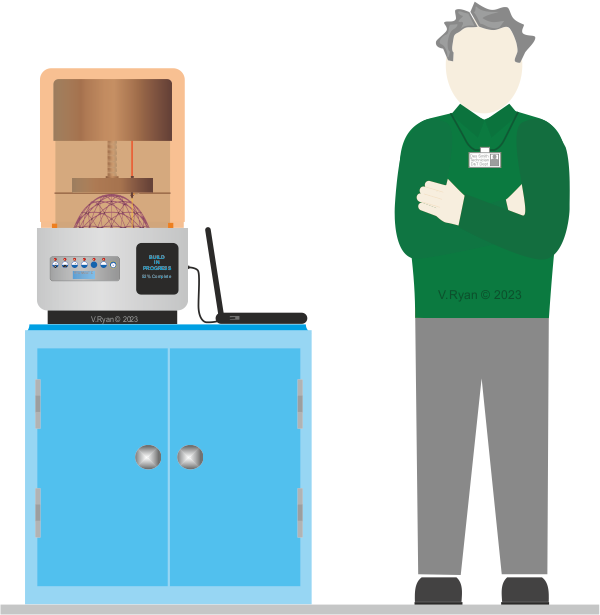

| DESKTOP STEREOLITHOGRAPHY - COMPARATIVE SIZE |

| |

|

| |

| |

| CLICK HERE FOR CNC INDEX PAGE |

| |

|

| |

|