| CLICK HERE FOR INDEX PAGE | |

| FLEXI PLY ( A FLEXIBLE FORM OF PLYWOOD) | |

| V. Ryan © 2013 | |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

|

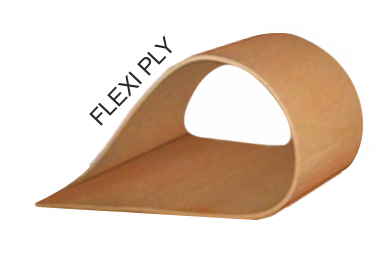

Flexi ply is a form of plywood but it is extremely flexible. Thin marine plywood can be forced to form curves and bends, but eventually it will split, if pressured too far. Normal plywood tends to resist bending. However, flexi ply is composed of layers of thin plies. This means that it will bend into various ‘curved’ shapes, quite easily. |

| Flexi Ply is ideal for a range of practical applications that require bends and curves. | |

|

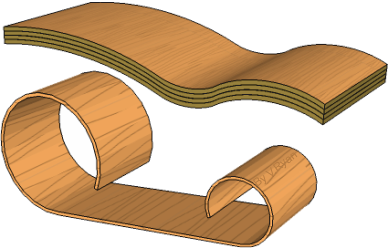

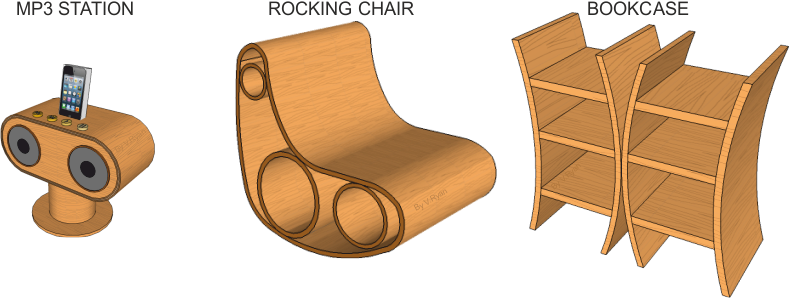

The drawing opposite, shows how layers of flexi ply can be formed into

unusual shapes. Three examples of flexi ply furniture are shown below. |

|

|

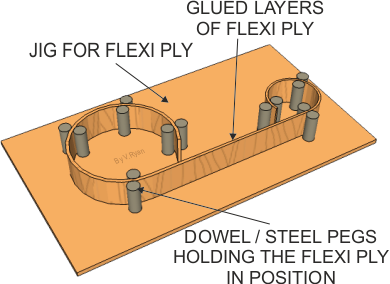

| USING A FORMER / MOULD / JIG WHEN FORMING FLEXI PLY | |

|

Normally a jig / mould / former is made first. Glue is applied to each layer of flexi ply. The various layers are held firmly in the jig, for twenty four hours, until the glue is dry. When the flexi ply is removed, the layers are permanently glued together, in the shape of the mould / jig. Using this technique, allows several layers of thin flexi ply to be glued together, permanently, forming curved shapes / forms. |

|

| CLICK HERE FOR DESIGN PROCESS INDEX PAGE | |