|

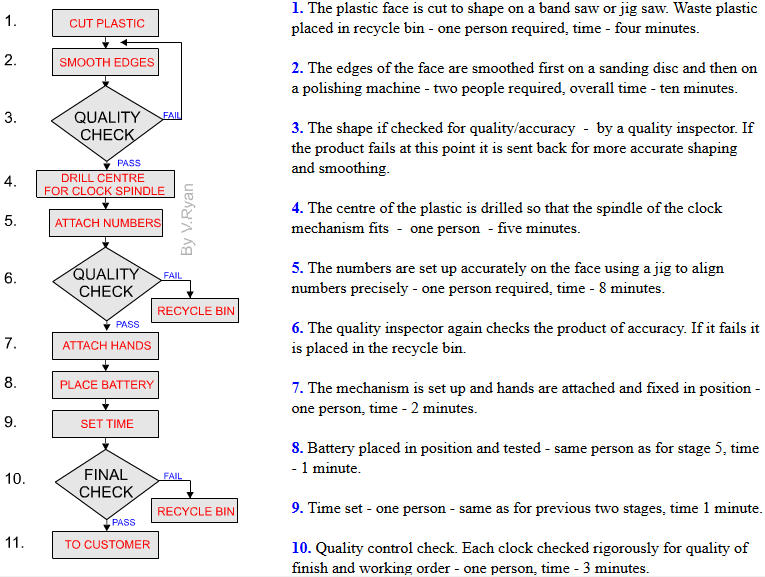

FLOWCHARTS PLANNING FOR MASS PRODUCTION V. Ryan © 2001-2014

|

||

| Planning the manufacture of a design, is an important aspect of the design process. Plain flowcharts are often associated with planning a mass production line, so that thousands of a product can be manufactured efficiently in a factory. At the beginning of the century, the first mass production line was set up in the USA. The Ford Motor Company set up a ‘line’ of workers who put together each 'Model T' car. The production line was composed of hundreds of people, each doing only one job. When you plan your production line, you need to keep each stage of manufacture very simple. This is planning for ‘mass production’. | ||

|

||

| PDF FILE - CLICK HERE FOR PRINTABLE PRODUCTION FLOWCHARTS | ||

| A SIMPLE PRODUCTION LINE FLOWCHART FOR THE ASSEMBLY OF A CLOCK FACE AND MECHANISM | ||

|

||

| A Word About Quality Control: | ||

|

When a product is manufactured, whether in a school workshop or on a production line in a factory, quality control is very important. At almost every stage of production, the quality of the work should be checked and any defects corrected. The flow chart above shows that the product is check three times. Each quality control point shown in the flow chart is called a critical control point. The overall quality of a product is checked by comparing it against quality control indicators. Some examples are shown below: |

||

|

|

||

|

Imagine you are to make a small coffee table. What could be the quality indicators for this product? |

||

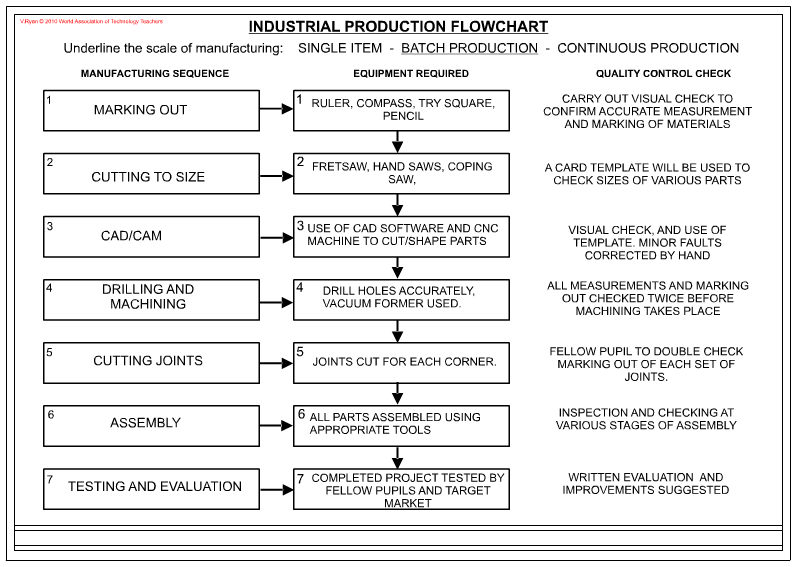

| PRESENTING A FLOWCHART - YOUR PROJECT | ||

|

A more detailed type of flow chart can be drawn, one that includes quality control at each stage of manufacture. Click here to see the basic layout. |

||

| EXAMPLE FLOW CHART WITH QUALITY CONTROL | ||

|

||

|

A flow chart can be presented in any way you think is appropriate. The boxes can be a shape that fits the product you are designing, in this case they could have been circles representing a clock face. Use your imagination ! |

||

|

Frequency of analysis: If the number of products to be manufacture is very small then every product is inspected. However, if large volumes are to be manufactured it is not economic to inspect every item - in this case sampling takes place. For example, one out of every hundred products may be quality checked with each sample checked against quality indicators. If a sample does not pass the quality check then the whole batch of one hundred would have to be individually checked. |

||

| CLICK HERE FOR GRAPHICS INDEX PAGE | ||