| |

| CLICK HERE FOR INDEX PAGE |

| |

| EXAMPLE - COMPLETED PAGES FROM LOGBOOK |

| V. Ryan © 2008 - 2010 |

| |

|

|

MANUFACTURING DESCRIPTION:

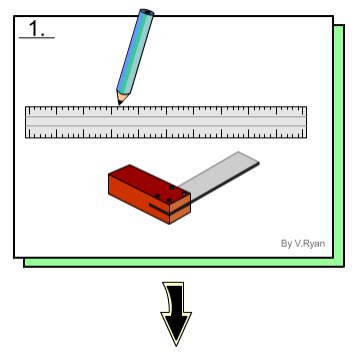

The materials are marked out using a range of tools including rulers, try

squares and marking gauges.

The materials were marked out accurately and checked twice before being

cut to size by hand tools and using machines.

IMPROVEMENTS:

Next time I will ask another person to check my marking out. In industry

this would mean asking a quality control manager to check my work.

Next time I will consider using card templates when marking out difficult

joints. |

| |

|

|

|

| |

|

|

|

MANUFACTURING DESCRIPTION:

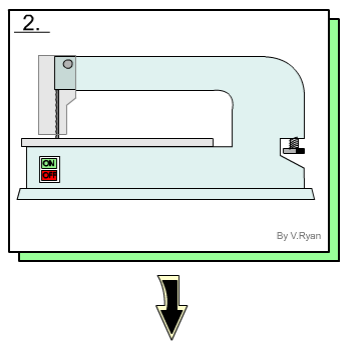

The materials are cut to size using a fretsaw and hand saws. All

measurements are checked before cutting. Using the fretsaw meant that the

work was cut accurately and with relative ease.

IMPROVEMENTS:

In future I will consider cutting some of the more difficult pieces using

a CNC machine, especially if several of the same type of pieces need

cutting. |

|

|

|

|

|

|

|

|

|

|

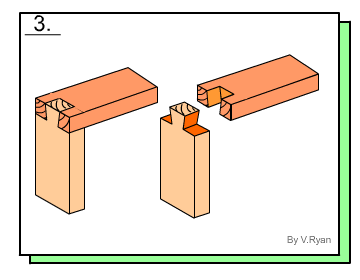

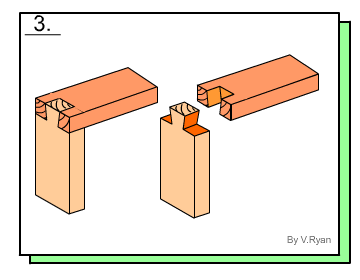

MANUFACTURING DESCRIPTION:

A number of joints were cut using hand tools such as tenon saws and

chisels. The fretsaw was also used and this time and increased accuracy.

IMPROVEMENTS:

I will consider using simple joints or even experimenting with stronger

glues. I may be able to avoid cutting joints. This will save time and

money. |

|

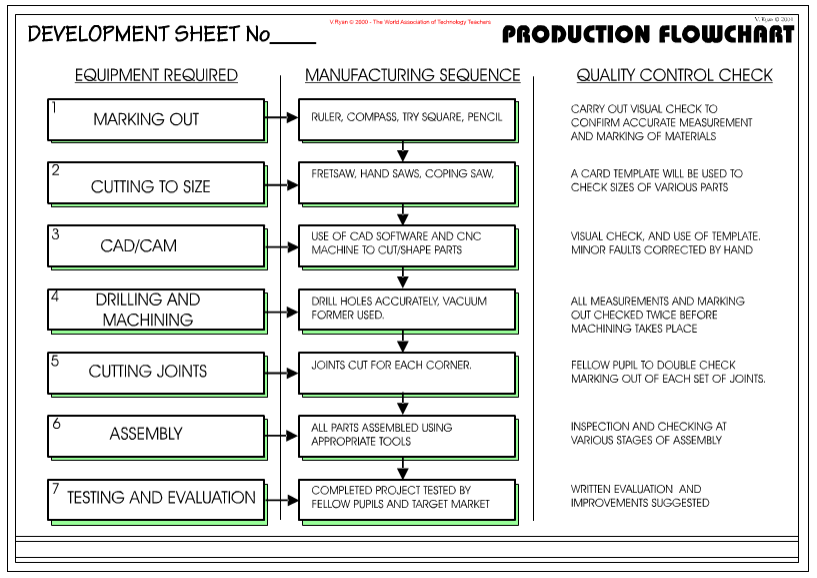

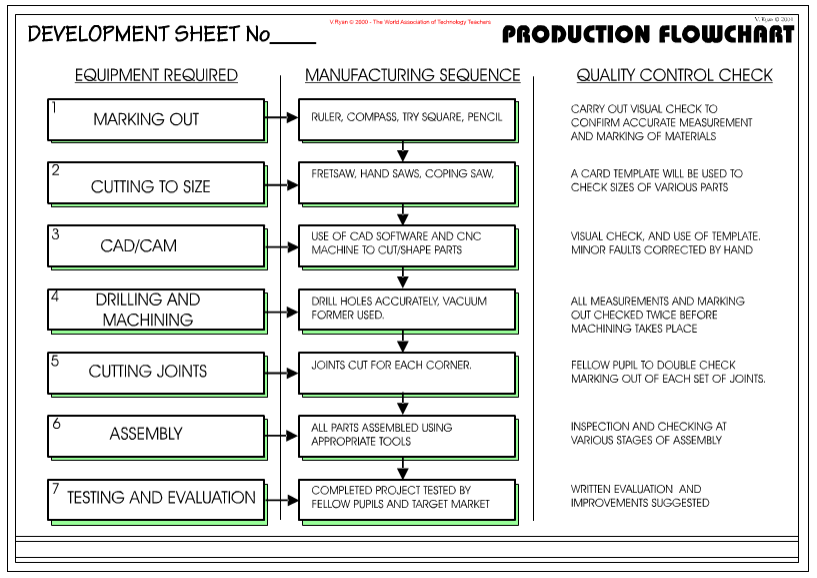

SAMPLE FLOW CHART PAGE |

|

( right click mouse to zoom in) |

|

| |

|

|

| |

| CLICK

HERE TO RETURN TO LOGBOOK PAGE |

| |

|

CLICK HERE FOR DESIGN PROCESS INDEX

PAGE |

| |

|