V.Ryan © 2018

| CLICK HERE FOR INDEX PAGE |

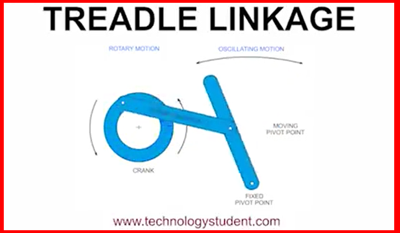

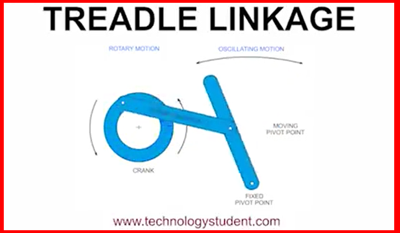

| TREADLE LINKAGE |

V.Ryan © 2018 |

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET |

| YOUTUBE VIDEO - TREADLE LINKAGES |

|

| A treadle linkage mechanism, converts rotary motion into an oscillating motion OR vice versa. The animation below, shows how the rotary motion of the wheel (crank) is converted to an oscillating motion, with the aid of the connecting rod. |

|

| Treadle linkages are not new and can be found on machines, dating back hundreds of years. Kirkpatrick Macmillan (Scotland, 1839), is traditionally credited with a machine (called the Treadle Bicycle) in which power was supplied to the back wheel, via rods connected to treadle-type pedals. The oscillating motion of the ‘pedals’, are converted to the rotary motion of the back wheel, via the connecting rods. |

|

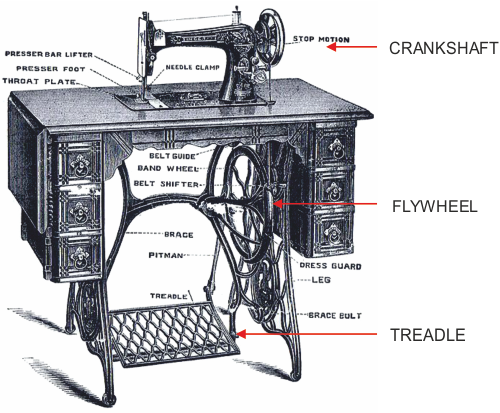

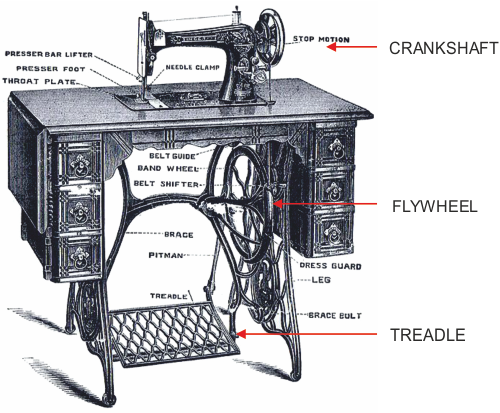

| VICTORIAN ‘SINGER’ TREADLE SEWING MACHINE |

| The ‘Singer Treadle Sewing Machine’, was powered by the oscillating motion of the the ‘treadle’, powered by the users feet. Connecting rods force a flywheel to rotate. The flywheel is connected to the rest of the machine by a leather belt, which drives a crankshaft at the back of the sewing machine. This sewing machine was very popular in Victorian times and was still in use up the 1950s, when many were converted to be powered by an electrical motor. |

|

| THE POWER HACKSAW |

| The power hacksaw is driven by a type of treadle linkage. The electric motor creates rotary motion of the pulleys wheels. Connecting rods help to create an oscillating motion of the hacksaw arm, which enables cutting of materials. |

|

|

| MODERN DAY FITNESS MACHINE |

| The modern fitness machine is operated by the user, powering the oscillating motion of the connecting rods, to push round the rotary motion of the back wheel. Resistance to the back wheel can be increased, making it more difficult for the user. All this is achieved through a treadle linkage system. |

|

| CLICK HERE FOR MECHANISMS INDEX PAGE |

|