| CLICK HERE FOR INDEX PAGE | |

| BRAZING USING A BRAZING HEARTH | |

| V. Ryan © 2002 - 2022 | |

|

Steel can be joined by using a technique called

brazing. A high temperature is needed for this and so a brazing hearth

is normally used. Brazing gives a permanent joint that is ideal for most

metalworking projects in schools and colleges. In industry this

technique is used on products such as bicycle frames where there is a

need for a certain amount of flexibility in the joint. |

|

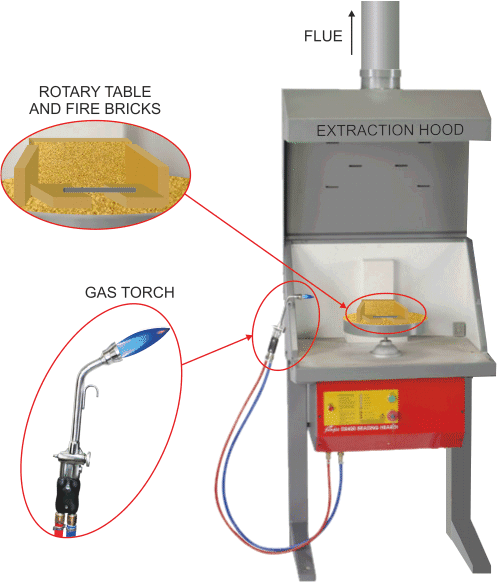

| THE EQUIPMENT | |

| (SEE BELOW) | |

| The brazing Hearth contains a compressor which

pressurises air and gas so that it is forced out the nozzle of a gas-air

torch. As it comes out the nozzle it can be ignited so that it burns

fiercely. If the torch is used correctly it can heat up metals to a high

temperature. This is exactly the type of equipment that is needed for a

brazing joint between two pieces of steel. Above the brazing hearth is an extractor. This extracts any fumes that collect during the heating process. The hearth normally has fire bricks arranged on its surface. These reflect heat back into the heating area so that high temperatures can be reached. A small rotating table is sometimes used to position the metals to be heated. |

|

|

|

|

|

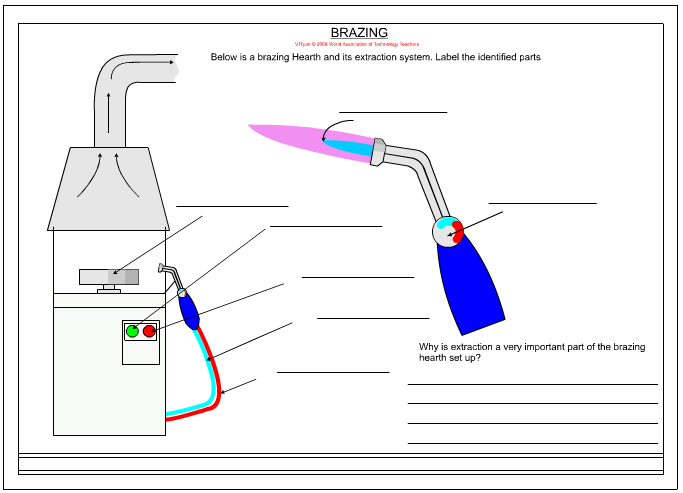

| PDF FILE - CLICK HERE FOR PRINTABLE VERSION OF EXERCISE SHOWN BELOW | |

|

|

|

QUESTIONS: |

|

|

|

|

|

|

|

|

|

|