| CLICK HERE FOR INDEX PAGE | |

|

WORKSHOP MACHINERY - THE FRETSAW |

|

|

V. Ryan © 2001 - 2022 |

|

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |

| PDF FILE - CLICK HERE FOR FRETSAW JIGSAW EXERCISE | |

| SHORT VIDEO - INTRODUCTION TO THE FRETSAW | |

|

|

|

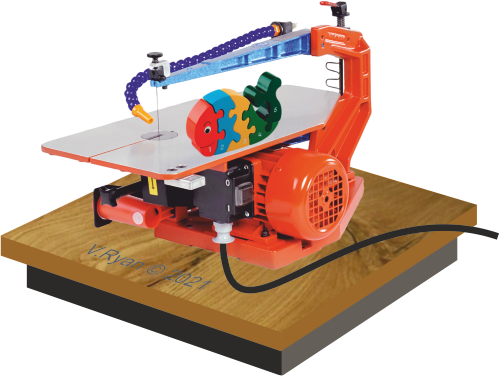

The scroll saw / fretsaw is a general workshop machine. It is used to

cut and shape light materials such as perspex, MDF and plywood. Fretsaws are

made by different companies and they range in price depending on the quality

of machine. The most expensive and probably the best are manufactured by the

German company ‘Hegner’. These can be used to cut very detailed shapes and

they are supplied with different types of blade according to the material

that is to be cut. |

|

|

|

|

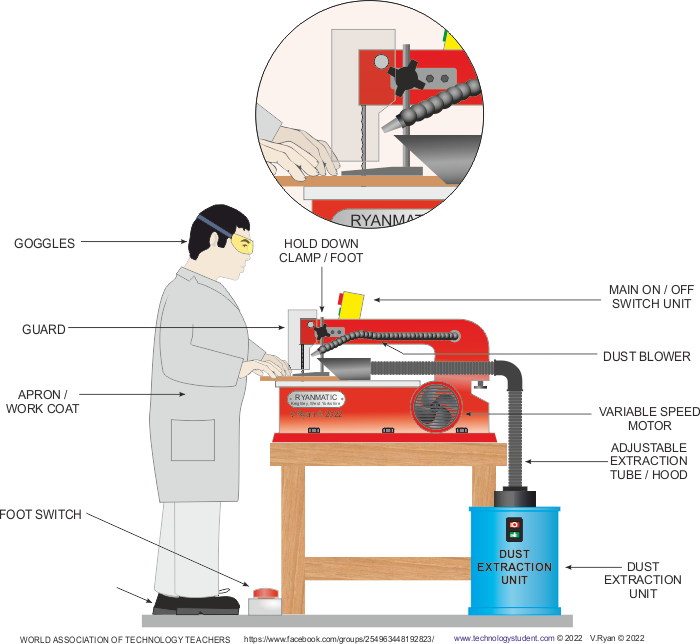

| TYPICAL USE | |

| Notice the use of the hold down clamp / foot. This is supplied with some scroll saws / machine fretsaws, and it holds down the materials being cut, stopping the materials lifting upwards. | |

|

|

|

|

| TYPICAL SCROLL SAW / MACHINE FRETSAW WITH SHAPED SAMPLE | |

|

|

|

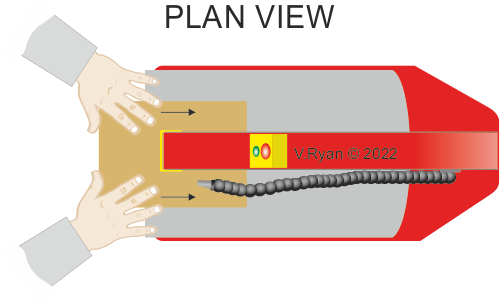

Although fretsaws are common machines they are still dangerous if the operator is careless and if he/she does not keep in mind safe working practices. It is important to use the guard is this is the first line of defence if a blade breaks. Goggles should also be worn for eye protection. The operator should know where the ‘on’ the ‘off’ buttons are and be able to use them. The material should be fed into the blade slowly and it needs to be gently held down on the table of the machine as this will prevent it from vibrating. The fretsaw should not be turned off whilst the blade is cutting the material especially if the material is then moved - this could twist the blade and it could be broken or damaged the next time the fretsaw is turned on. |

|

|

The fretsaw blade can be seen to the right. The blade is always set up in the fretsaw with the teeth pointing downwards. If the blade is set up the wrong way round, with the teeth pointing upwards - when the fretsaw is turned on the material will lift from the table and the blade may shatter. |

|

| QUESTIONS | |

| 1. The Fretsaw is a general workshop machine. What materials can be cut and shaped using this machine? | |

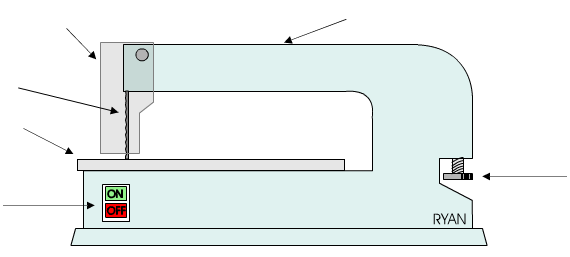

| 2. Label the parts of the fretsaw identified by the arrows on the diagram below. | |

|

|

| 3. Describe how the machine can be operated safely. | |

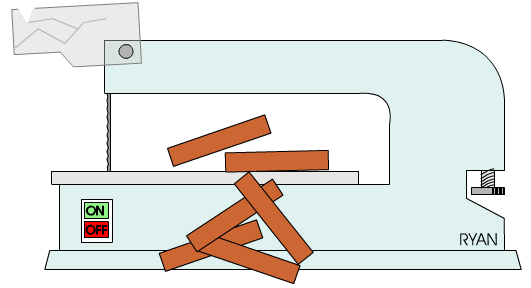

| 4. Look carefully at the fretsaw seen below. What is wrong with the way it has been left for the next user/operator? | |

|

|

| Click here for Unsafe Use of the Scroll Saw / Machine Fretsaw | |

| Click here for SAFE AND PROPER USE of the Scroll Saw / Machine Fretsaw | |

|

|

|