| CLICK HERE FOR INDEX PAGE | |

| INJECTION MOULDING OF PLASTICS | |

| V. Ryan © 2002 - 2022 | |

| Injection Blow Moulding - Box Learning Exercise | |

|

|

| VIDEO OF INJECTION MOULDING | |

|

|

|

|

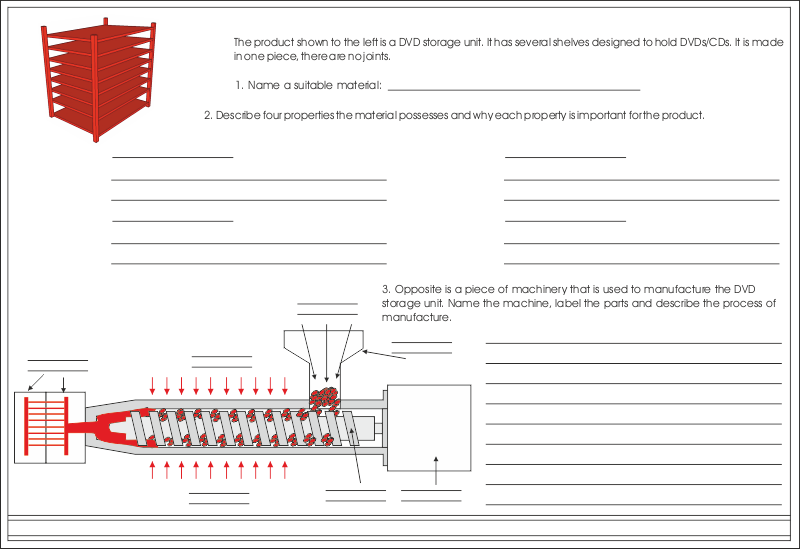

Materials such as polystyrene, nylon, polypropylene and

polythene can be used in a process called injection moulding. These are

thermoplastics - this means when they are heated and then pressured in a

mould they can be formed into different shapes. The DVD Storage unit seen opposite has been made in one piece using this process An animation of an injection moulding machine is shown below. The product being produced is the DVD / CD storage unit seen opposite. |

|

|

|

|

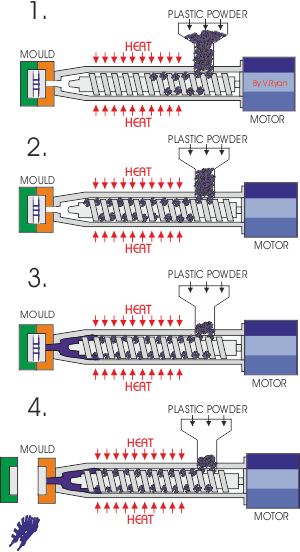

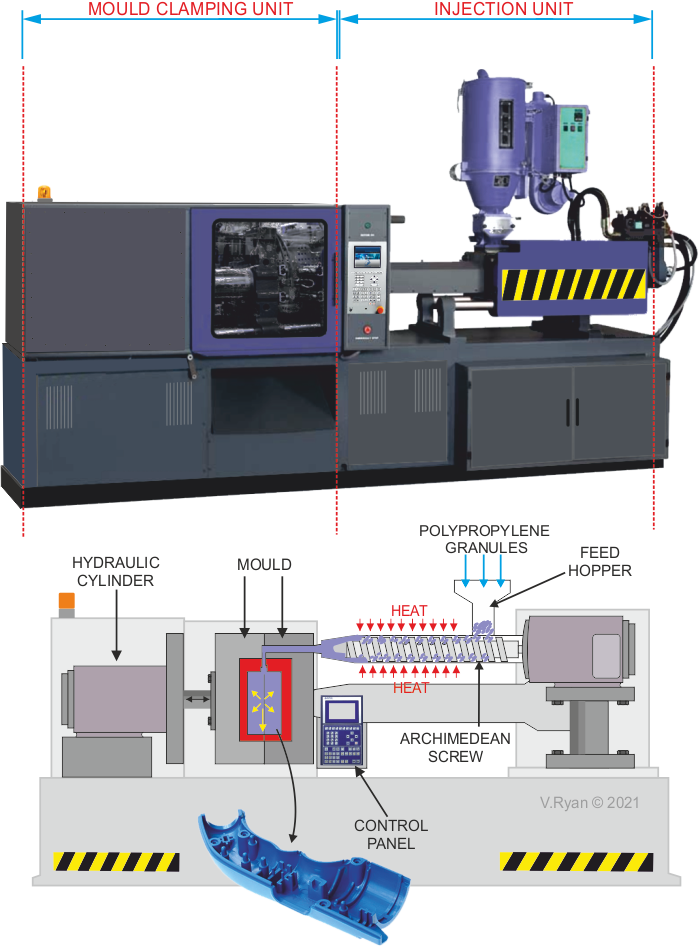

1. Granules of plastic powder (note the plastics listed above) are poured or fed into a hopper which stores it until it is needed.

3. A motor turns a

thread which pushes the granules along the heater section which melts then

into a liquid. The liquid is forced into a mould where it cools into

the shape (in this case a DVD storage unit). 4. The mould then opens and the unit is removed. |

| PDF FILE - CLICK HERE FOR PRINTABLE VERSION OF WORKSHEET SHOWN BELOW | |

|

|

|

|

|

| CLICK HERE FOR FURTHER INJECTION MOULDING | |

| INDUSTRIAL / COMMERCIAL INJECTION MOIULDING MACHINE | |

|

|

| List products that have

been manufactured through injection moulding.

|

|

|

|

|