| CLICK HERE FOR INDEX PAGE | |

| CASTING PEWTER - 1 | |

| V. Ryan © 2006 - 2009 | |

|

Pewter is an ALLOY which means it is composed of more than one metal. Most modern pewter is composed of 96 percent tin and 4 percent copper although there are many variations. It is a soft metal and can be shaped easily by hand tools and machine tools. Due to its low melting point (approximately 230 degrees centigrade) it is suitable for casting. It is a bright material, which makes it popular for the manufacture of ‘silverware’ such as tankards, candlesticks and even jewellery. |

|

|

Pewter can be purchased as ingots and a typical ingot is shown below. Because pewter is malleable (soft) it can be cut with a hacksaw easily. When preparing to cast pewter small pieces of approximately 60mm in length are cut. This size will fit comfortably in the ‘bowl’ of a casting ladle, ready for casting. |

|

|

|

|

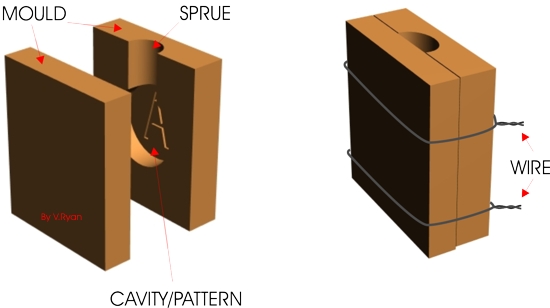

Before casting can take place a mould must be made. Moulds can be made from a range of materials including MDF, steel, silica sand or even oil based casting sands such as ‘petrabond’. In schools and colleges, MDF is an ideal material and moulds made from this material can be reused a small number of times. An example of a mould is seen below. It has two parts and they are held together with wire or small cramps. |

|

|

|

|

The pattern/cavity can be cut in the MDF using hand tools or for accurate results a CNC machine can be used. A natural material such as Cuttlefish bone can also be used. Cuttlefish bone is a soft material and is the shell of the cuttlefish usually found in the Indian Ocean. It can be craved into detailed shapes and in this way a pattern can be cut into its surface and this can be used as the mould. |

|

| CLICK HERE FOR NEXT PEWTER CASTING PAGE | |

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE | |