| CLICK HERE FOR INDEX PAGE | |||||||||||||||||||||

| THE SHAPING MACHINE | |||||||||||||||||||||

| V. Ryan © 2003 - 2023 | |||||||||||||||||||||

| PDF FILE - CLICK HERE FOR PRINTABLE WORKSHEET | |||||||||||||||||||||

| YouTube Video - Introduction to the Shaping Machine | |||||||||||||||||||||

|

|||||||||||||||||||||

|

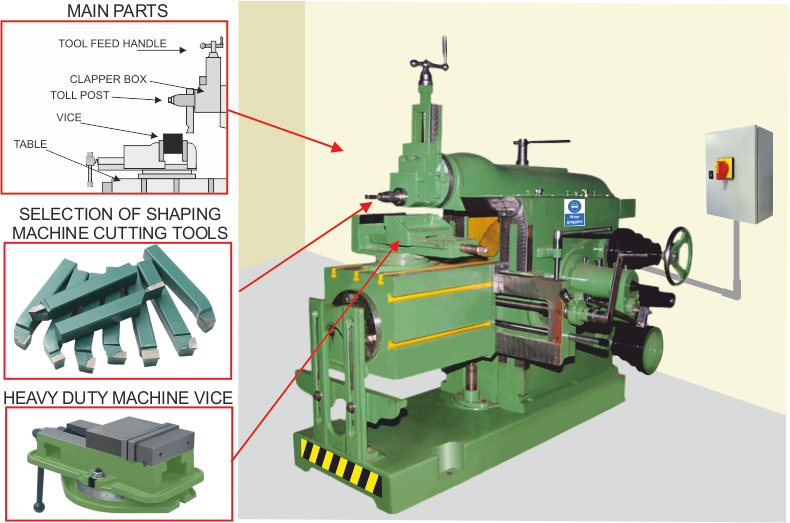

A shaping machine is used to machine surfaces. It can cut curves, angles and many other shapes. It is a popular machine in a workshop because its movement is very simple although it can produce a variety of work. Shaping machines come in a range of sizes but the most common size is seen below.

|

|||||||||||||||||||||

| PHOTO-REALISTIC IMAGE OF A TYPICAL SHAPING MACHINE | |||||||||||||||||||||

|

|||||||||||||||||||||

|

|||||||||||||||||||||

|

|

|||||||||||||||||||||

|

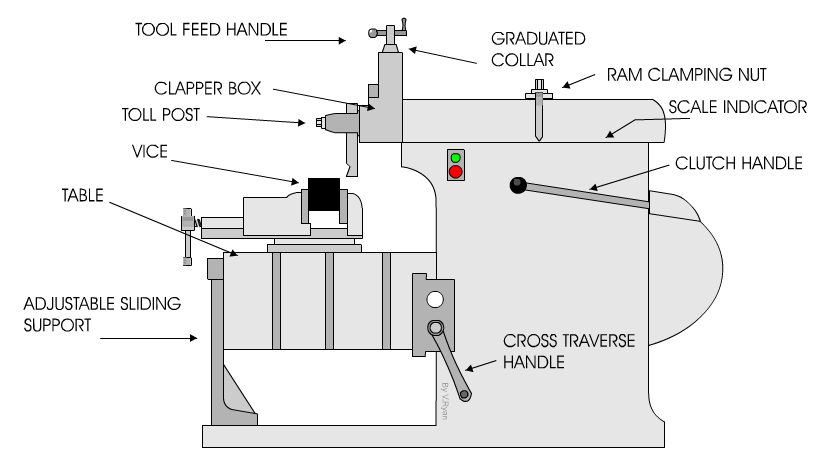

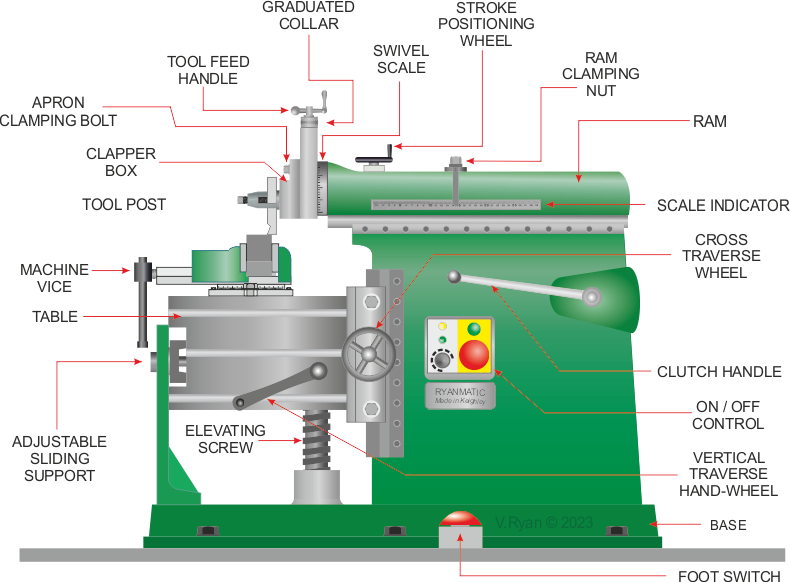

The main parts are indicated below: The tool feed handle can be turned to slowly feed the cutting tool into the material as the 'ram' moves forwards and backwards. The strong machine vice holds the material securely. A small vice would not be suitable as the work could quite easily be pulled out of position and be damaged. The vice rests on a steel table which can be adjusted so that it ca be moved up and down and then locked in position. Pulling back on the clutch handle starts the 'ram' moving forwards and backwards. |

|||||||||||||||||||||

|

|

|||||||||||||||||||||

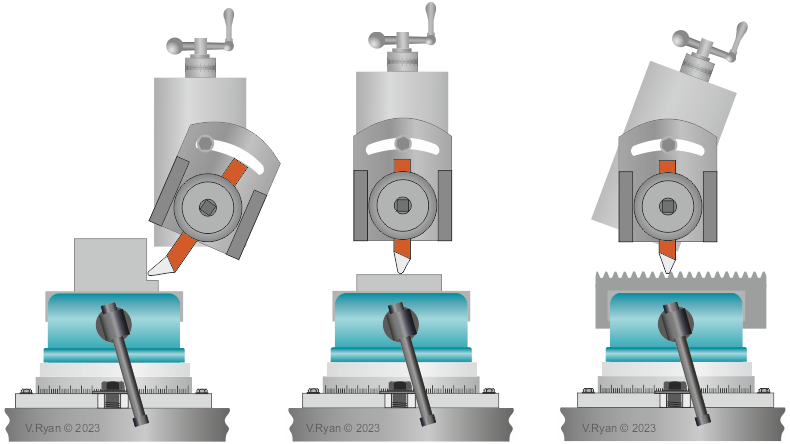

| The tool post and the tool slide can be angled as seen below. This allows the shaper to be used for different types of work | |||||||||||||||||||||

|

|||||||||||||||||||||

|

QUESTIONS: 1. Draw a diagram to represent a shaping machine and label the important parts. 2. Describe the type of work carried out by these types of machines. |

|||||||||||||||||||||

|

|

|||||||||||||||||||||