THE VERTICAL MILLER (2)

MAKING ADJUSTMENTS AND SECURING MATERIAL

Usually, the ‘feed’ of the machine can be set to automatic so that there is no need to turn the handles manually.

| CLICK HERE FOR INDEX PAGE | ||

THE VERTICAL MILLER (2) MAKING ADJUSTMENTS AND SECURING MATERIAL |

||

| V. Ryan © 2003 - 2022 | ||

| The vertical traverse hand wheel (handle) is turned in order to raise or lower the knee. This means that the machine vice is also raised or lowered towards or away from the cutting tool. | ||

|

||

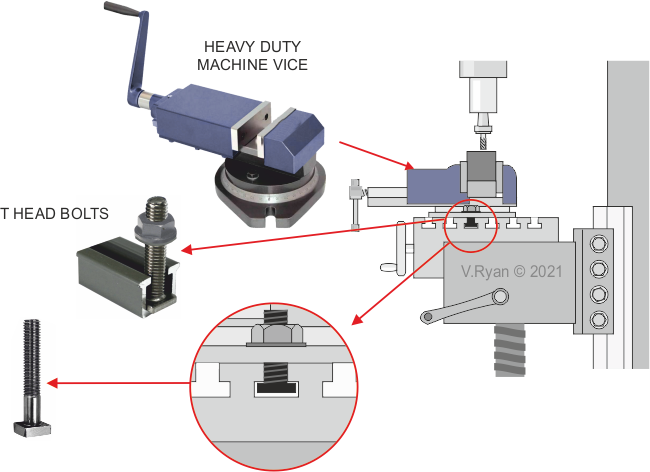

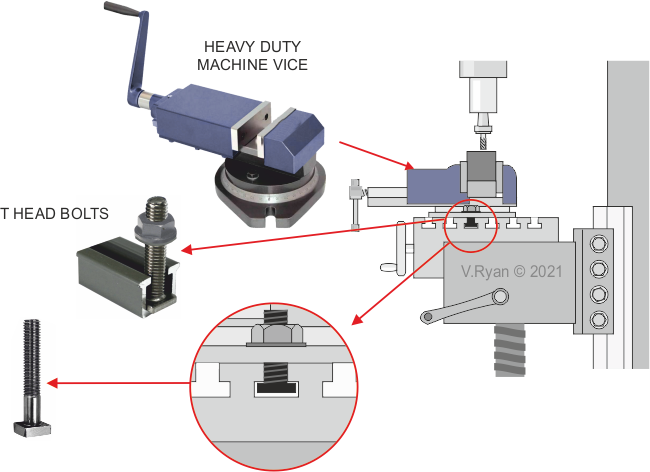

| USING T BOLTS AND A HEAVY DUTY MACHINE VICE | ||

|

||

| Used when there is a need to bolt a device such as a machine vice to a milling machine table, ready for machining. In this example, T Bolts are used to secure the machine vice | ||

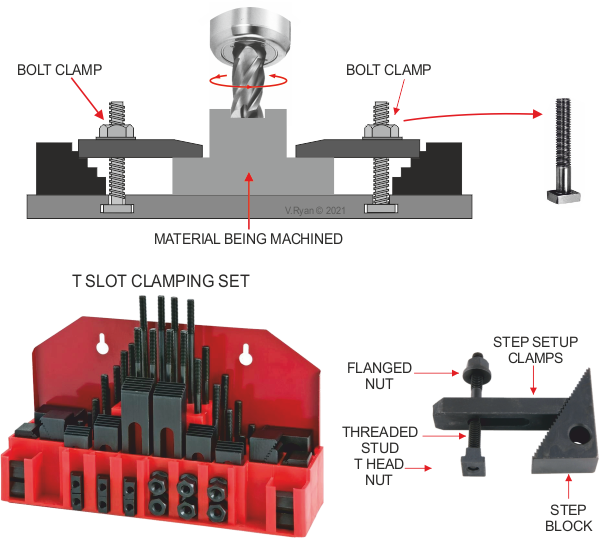

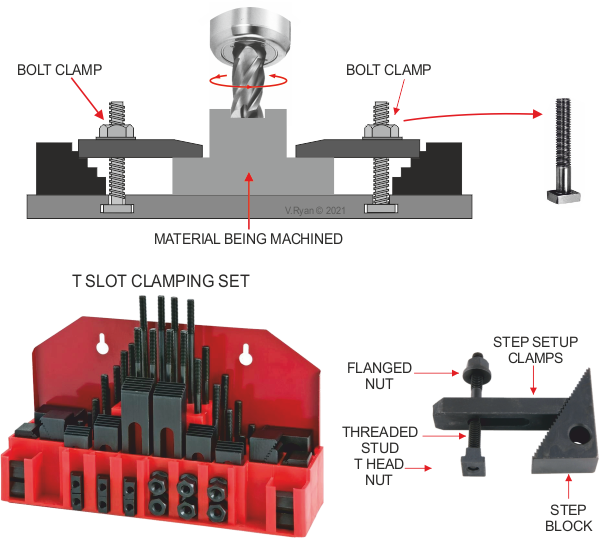

| The clamping set seen below, holds an aluminium rough casting down on the table of a vertical miller, ready for machining. Two T Bolts can be clearly seen. This is an effective method of securing castings, that cannot fit into a machine vice. T Bolts are easy to use and can be tightened and loosened easily. | ||

|

||

| The machine head can be tilted to a variety of angles allowing chamfers to be machined. Normally this is done by slowly loosening a number of bolts and then tilting the machine head to the required angle. Some machines have a gauge on which angles can be read so that it can be set accurately. | ||

|

||

| The feed handle is turned by the machine operator.

This moves the table and anything bolted to it (such as a vice) towards

the cutting tool. Usually, the ‘feed’ of the machine can be set to automatic so that there is no need to turn the handles manually. |

||

|

||

| CLICK HERE FOR NEXT VERTICAL MILLER PAGE | ||

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE | ||