SMALL SCALE ALUMINIUM CASTING

PREPARING THE DRAG (BOTTOM BOX)

Sometimes it is necessary to pack the drag so that the sand is not highly compressed in the area of the pattern. This allows the pattern to be pressed into the sand more easily.

| CLICK HERE FOR INDEX PAGE | ||

SMALL SCALE ALUMINIUM CASTING PREPARING THE DRAG (BOTTOM BOX) |

||

| V. Ryan © 2008 - 2009 | ||

|

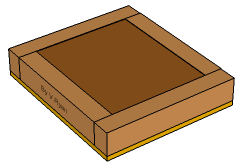

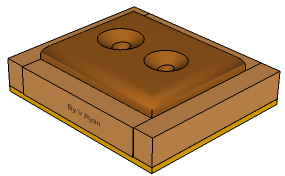

The sides of the second box are placed on top of a base. Note, the base is plain and does not have holes for sprues, unlike the ‘cope’. | |

|

Petrabond casting sand is sieved in the same way as for the ‘cope’. Hands and fingers are used to compress the sand so that it is not loose. If not compressed, the sand will collapse when the box is moved. | |

| A strickling bar (steel rod) is used to level the sand with the top of the ‘drag’. | ||

|

|

|

|

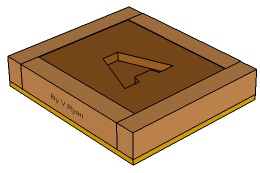

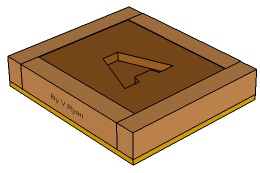

The pattern, in this case a letter is pressed into the

sand. The pattern must have a draft to each edge. This is a slight incline

that allows the pattern to be removed from the sand. Sometimes it is necessary to pack the drag so that the sand is not highly compressed in the area of the pattern. This allows the pattern to be pressed into the sand more easily. |

|

| If necessary, the strickling bar is used to level the surface again. Sometimes pushing the pattern into position disturbs the sand especially around the edges of the pattern. If this happens more fine sand can be placed over the top of the pattern and compressed. The strickling bar can then be used to level the surface for a final time. | ||

|

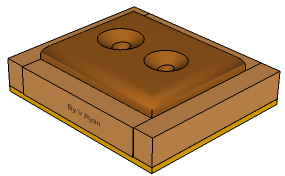

The pattern is carefully removed. If the pattern has a pre-drilled hole in its back, a screw can be inserted and the pattern freed by tapping it side to side. The pattern can then be lifted out of the sand. This reveals the cavity into which the molten aluminium will be poured. | |

|

The ‘cope’ is then placed on the top of the drag. The cope and drag can be held together by a small weight or by screws. When the aluminium is poured the pressure can lift the cope out of position if the casting boxes are not secured or held together in this way. | |

| Cope and Drag in position ready for the molten aluminium. | ||

|

||

| CLICK HERE FOR NEXT SMALL SCALE ALUMINIUM CASTING PAGE | ||

| CLICK HERE FOR EQUIPMENT AND PROCESSES INDEX PAGE | ||

|

|