V.Ryan © 2022

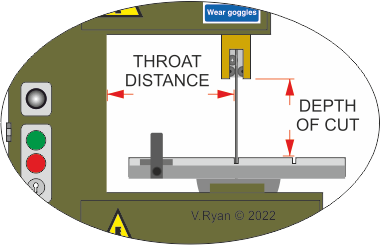

The blade guard can be raised to accommodate thicker pieces of material. This is called the ‘depth of cut’. However, the thicker the material the slower the cutting process. After experience in using a band saw, the machine operator will determine the safe maximum thickness, that the band saw can safety cut.

The ‘throat distance’ determines the width of the cut. This is the distance between the blade and the inner edge of the band saw. The wider the throat distance, the wider the width of material that can be cut.

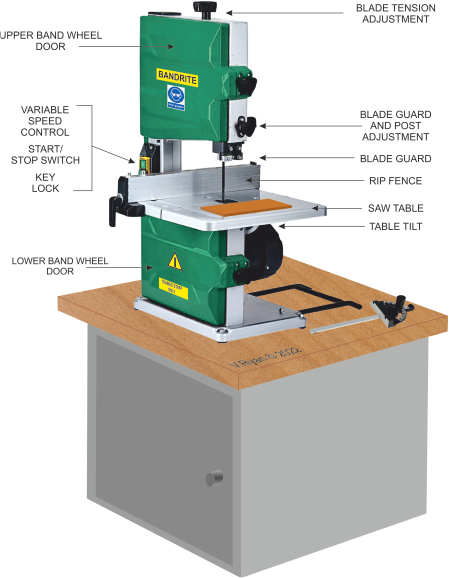

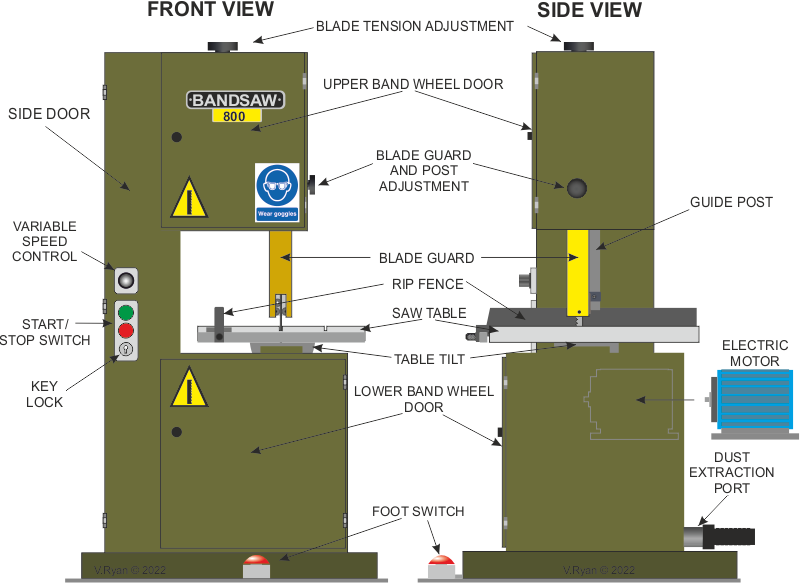

The variable speed control unit, is a dial that can be turned to increase / reduce, the cutting speed of the blade. On a band saw, the speed is the metres / feet that the blade travels in one minute (also referred to as, Surface Feet Per Minute (SFM)). As a general rule, slower speeds are for cutting harder materials, such as metals and faster speeds are recommend when cutting woods. It takes experience in the use of the band saw, to set the correct speed.

General guidance - for a blade with a high number of teeth per inch (TPI), use a slower cutting speed. For a low number of teeth per inch, use a faster speed.

A safety feature of some band saws is the key lock. The trained machine operator, unlocks the start / stop control unit before use. If leaving the machine, to select material from the storeroom, the operator should lock the start / stop unit. If the unit is locked, the machine will not start. This prevents unauthorised / untrained people operating the band saw.

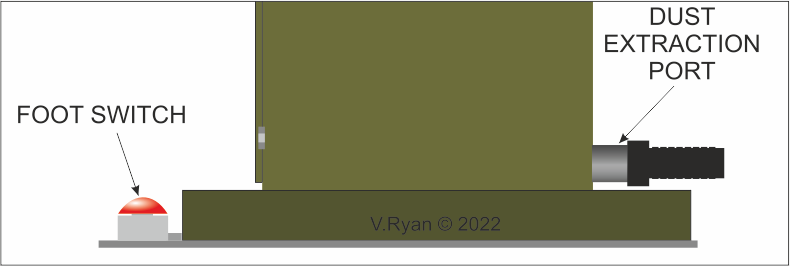

In schools and factories, band saws are fitted with a foot switch. The foot switch allows the machine operator, to switch off the power with his / her foot, whilst controlling the material with both hands. It is also an additional safety feature. The foot switch is a quick and convenient way of turning power off, especially in an emergency.

Band saws create dust when cutting through material, such as wood. Dust is dangerous and every effort must be made to ‘extract’ it, before it is suspended in the air and breathed in. A dust extractor removes floating dust particles before they escape the machine. Some band saws are fitted with additional extraction near the blade. If the dust is allowed to accumulate inside the machine, it can interfere with the smooth running of the wheels, eventually jamming the blade and potentially damaging the band saw.