V.Ryan © 2022

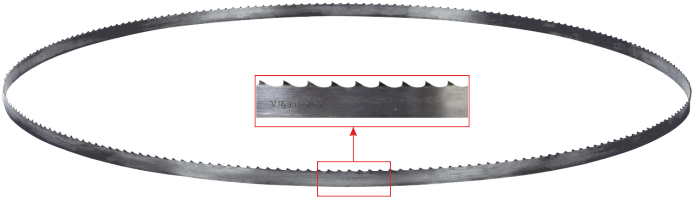

The first stage is to unfold the rings, so that it is a single loop. Remove the string / wire holding the loop in three rings. Throwing the blade to the floor, will often force the blade to untangle and spring into the single loop.

Open the upper / lower and side door of the band saw. Reduce the tension on the old blade by turning the tension adjuster, lower the top band wheel.

Remove the blade guard, to reveal the full length / loop of the old blade.

Carefully remove the blade and fold it, in order to store or ready for disposal.

Place the new blade over the top band wheel, with the teeth pointing downwards and facing the machine operator, as shown opposite. Also ensure that the blade runs around the bottom wheel.

The blade is usually positioned, so that it rests in the centre of the ‘edge’, of the top band wheel.

Apply a little tension to the blade, by turning the tension adjuster.

Spin the top wheel and check that the blade stays in the centre of the edge.

If the blade does not stay in the centre of the edge, adjust the tracking by turning the tracking control clockwise / anticlockwise. Spin the top wheel until the blades stays centrally on the edge.

Apply the recommended amount of tension to the blade and close the doors.

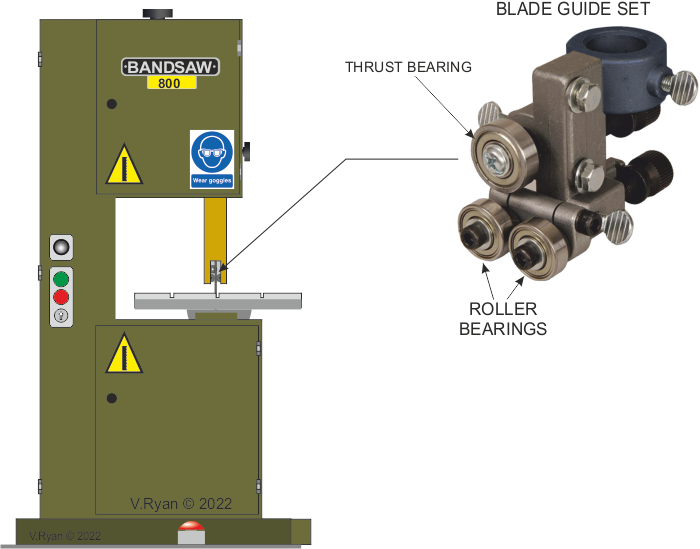

Now, set up / adjust the Blade Guide Set.

The back of the blade rests against the thrust bearing, when cutting (when setting up, there should be a minimum gap between the blade and the thrust bearing).

The distance between the table and guide set, is adjusted according to the thickness of the material being cut.

Now, turn on the band saw and check the blade runs true and accurate. Let the motor run for minute. If all appears to be working properly, the band saw is ready for use.